My First Encounter with Sculpting Ball-Jointed Dolls: A Creative Awakening

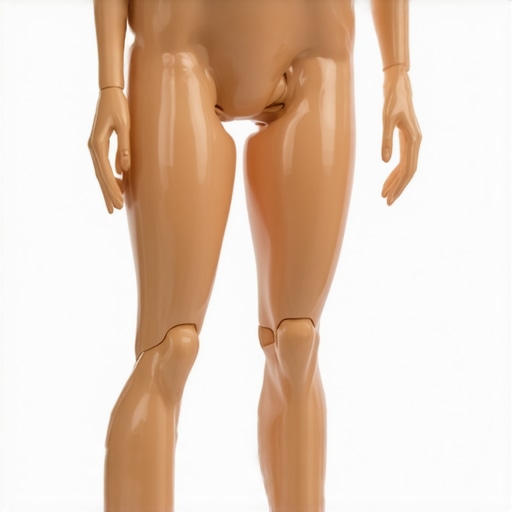

It all started on a rainy weekend when I decided to explore a new hobby—crafting my own ball-jointed dolls. I was fascinated by their intricate articulation and expressive features. My first attempt involved shaping polymer clay into tiny, delicate parts, and I quickly realized the importance of patience and attention to detail. This journey transformed my understanding of DIY crafts and inspired me to master the art of doll-making.

Delving into Polymer Clay: The Versatility of a Creative Medium

Polymer clay became my go-to material because of its flexibility and vibrant colors. I discovered that with practice, I could create highly realistic features, from tiny fingers to expressive faces. The key was to work slowly and build layers, much like a sculptor refining a statue. For inspiration, I often visited sites like home improvement tips for innovative techniques that could be adapted to my dolls. Polymer clay also allows for seamless articulation, which is essential for creating dolls that can pose naturally.

Resin Casting: Elevating the Craft with Durable Materials

Once I mastered polymer clay, I ventured into resin casting to create durable, glossy doll parts. Resin offers a stunning finish and can be tinted with pigments for realistic skin tones. I learned that proper mixing and curing are critical, and I often consult authoritative sources like advanced craft guides to improve my techniques. Resin also expands creative possibilities, such as embedding tiny objects or creating transparent limbs that mimic glass. It’s a game-changer for serious doll artists like me.

What’s the Secret to Making Your Dolls Truly Unique?

In my experience, adding personalized touches—like hand-painted eyes or custom outfits—makes all the difference. I also enjoy experimenting with different textures and finishes to give each doll its own personality. Sharing my progress in online communities has been invaluable, as I receive feedback and new ideas that push my skills further. If you’re curious about the creative process, I highly recommend exploring DIY projects that can complement doll-making, like miniature furniture or accessories.

Would you like to learn more about the best tools and techniques for sculpting and articulating dolls?

Feel free to comment below or share your own experiences. The journey of creating beautiful, articulate dolls is endlessly rewarding and full of surprises. Remember, the key is to experiment and enjoy every step of the process.

Unlocking the Secrets of Complex Articulation in Doll Sculpting

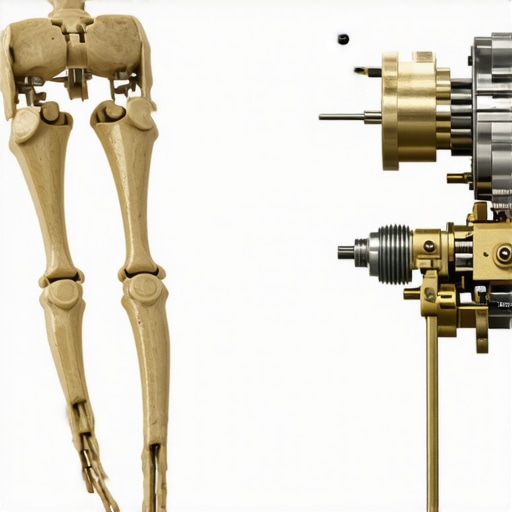

As an experienced doll artist, I can attest that achieving realistic and highly articulated ball-jointed dolls requires a nuanced understanding of both anatomy and materials. The intricacies of joint design, such as incorporating complex mechanical features, are pivotal in creating dolls that move naturally and expressively. Mastering these elements involves studying human biomechanics and applying precise engineering principles to miniature scale structures.

Advanced Material Integration: Combining Polymer Clay, Resin, and Mechanical Systems

Blending different materials elevates the realism and durability of your dolls. For example, polymer clay can be used for detailed facial features, while resin provides glossy, skin-like finishes for limbs. Integrating tiny mechanical systems within the joints—such as miniature gears or tension wires—can enhance poseability. This approach demands meticulous planning and a deep knowledge of precision joint construction techniques. The key is to ensure seamless movement without compromising the aesthetic appeal.

What Are the Most Common Pitfalls in Complex Doll Sculpting and How to Avoid Them?

Many seasoned artists encounter challenges such as joint instability, uneven articulation, or material cracking over time. To mitigate these issues, I recommend thorough research into joint reinforcement methods and practicing with small prototypes before committing to full-scale dolls. Additionally, understanding the curing and drying processes of different materials—like polymer clay baking or resin curing—is crucial in preventing deformation. Combining expert techniques with patience and iterative testing leads to more refined results.

How Can I Personalize My Dolls to Stand Out in a Competitive Market?

Personalization is the hallmark of a master doll maker. Custom painting, intricate clothing, and unique accessories imbue each piece with character. Experimenting with mixed media—such as fabric, leather, and tiny props—can create a distinctive style. Sharing progress on platforms like home decor DIY communities not only garners feedback but also inspires new ideas. Remember, the essence of expert craftsmanship lies in attention to detail and the willingness to push creative boundaries.

For further inspiration, exploring DIY crafts that involve miniature modeling or accessory-making can expand your skill set and add depth to your doll creations.

Would you like to delve deeper into the technical aspects of joint engineering or explore innovative finishing techniques? Feel free to comment below or share your experiences. The world of doll sculpting is vast and full of possibilities—embrace the challenge and enjoy every step of your artistic journey.

Deepening the Craft: My Journey into Advanced Doll Articulation

As I ventured further into the world of doll sculpting, I realized that achieving truly natural and expressive movement requires a meticulous understanding of biomechanics and mechanical engineering principles. My exploration led me to study detailed joint design, where I experimented with incorporating complex mechanical features such as miniature gears, tension wires, and ball-and-socket joints. These innovations significantly enhanced the poseability and realism of my dolls, allowing for a wide range of natural movements that mimic human articulation.

In my experience, mastering these elements involves a delicate balance—ensuring joints are both flexible and durable, without sacrificing aesthetic integrity. The challenge was to design miniature systems that could withstand repeated movement while maintaining seamless aesthetics. I often revisit authoritative sources and community forums to refine my techniques, such as studying precision joint construction techniques, which are crucial even at a miniature scale. This ongoing learning process has been instrumental in pushing the boundaries of what I thought possible in doll articulation.

Integrating Multiple Materials for Hyper-Realistic Results

One of the most rewarding aspects of my advanced work has been integrating different materials—polymer clay, resin, and tiny mechanical parts—to create hyper-realistic, durable dolls. Polymer clay is perfect for detailed facial features, offering sculptural finesse, while resin imparts a glossy, skin-like finish for limbs that can embed embedded tiny objects or even incorporate transparent sections that mimic glass. The key to successful integration is meticulous planning: I design the mechanical system first, ensuring proper placement within the doll’s structure, before sculpting or casting the outer layers.

Embedding miniature gears or tension wires within resin limbs has opened new creative avenues. These internal systems allow for enhanced poseability, making the dolls more interactive and expressive. I’ve learned that understanding joint reinforcement methods is essential to prevent wear and tear over time, especially with frequent repositioning. This integration demands precision, patience, and an eye for detail, transforming simple sculptures into fully articulated works of art.

What Are the Most Overlooked Nuances in Achieving Authentic Movement?

This question has haunted me at times—what subtle details make a doll’s movement convincingly human? Through my journey, I discovered that small adjustments in joint tension, the placement of pivot points, and even the choice of materials for internal components can dramatically influence the doll’s expressiveness. For example, using a slightly softer tension wire allows for natural resistance, mimicking muscle tension and relaxation. Moreover, paying attention to the angles of joints and their range of motion ensures that movements are realistic and not stiff or exaggerated.

Incorporating these nuanced details, I found, is what elevates a doll from a well-crafted figure to a true piece of art that can convey emotion and personality. Sharing my progress and seeking feedback from online communities like home decor DIY enthusiasts and fellow artisans has been invaluable in refining my techniques. Their insights often highlight overlooked aspects—like the importance of smooth joint rotation or subtle material flex—that I might not notice alone.

If you’re passionate about doll sculpting or advanced modeling, I encourage you to experiment with these complex systems and share your discoveries. The journey of mastering articulations is ongoing, and every new technique or insight brings you closer to creating dolls that are truly lifelike and full of personality. Feel free to comment below or explore further techniques on advanced craft guides. Let’s continue pushing the boundaries of what’s possible together in this fascinating craft.

Refining the Art of Joint Mechanics for Unparalleled Expressiveness

Achieving authentic and fluid movement in ball-jointed dolls hinges on a profound understanding of joint mechanics and the subtle interplay of materials. My exploration into this realm has led me to develop innovative solutions such as integrating miniature ball-and-socket joints with tension wires, which mimic the natural resistance and relaxation of human muscles. This approach not only enhances poseability but also preserves the aesthetic integrity of the doll’s form. Delving into detailed biomechanical studies, I have adapted principles from human anatomy to miniature engineering, ensuring each joint offers a seamless range of motion while maintaining durability.

Harnessing Material Science for Seamless Mechanical Integration

The complexity of embedding mechanical systems within delicate sculptures requires meticulous material selection and precise craftsmanship. I frequently utilize high-strength, flexible resins combined with lightweight metals like titanium or stainless steel for internal components. These materials are chosen for their resilience and compatibility with polymer clay and resin overlays. The process begins with designing miniature gears via CAD software, followed by casting or 3D printing these parts to exact specifications. Embedding these within the doll’s structure demands careful planning, ensuring that internal mechanisms do not compromise external aesthetics or pose stability.

How Can I Innovate Further in Doll Articulation to Capture Subtle Movements?

This question has driven my ongoing quest for realism. To capture nuanced expressions—such as a gentle tilt of the head, a subtle shrug, or delicate hand gestures—I experiment with micro-tension systems and soft-tissue simulation techniques. Using materials like silicone or gel inserts, I can add a layer of softness that emulates skin pliability, further enhancing realism. Additionally, employing miniature servo motors or smart actuators controlled via microcontrollers offers programmable movement capabilities, enabling dynamic posing and lifelike animations. Consulting authoritative sources such as advanced craft guides provides valuable insights into integrating complex mechanical systems at miniature scales.

Encouraging fellow artisans to share their innovations and challenges fosters a collaborative environment where continuous learning thrives. I invite you to explore these advanced techniques, experiment with materials, and push the boundaries of what’s possible in doll articulation. Your creative journey can lead to masterpieces that convey emotion with astonishing authenticity, much like the works I strive to perfect every day.

Things I Wish I Knew Earlier (or You Might Find Surprising)

Understanding Joint Mechanics

When I first started sculpting ball-jointed dolls, I underestimated how crucial precise joint design was. It’s not just about aesthetics; the internal mechanics determine how naturally the doll can move. Realizing this early on would have saved me countless hours of trial and error.

The Power of Material Compatibility

Mixing different materials like polymer clay, resin, and internal mechanical parts requires careful planning. I used to struggle with joints cracking or becoming loose over time. Learning about material compatibility beforehand made a huge difference in the durability of my creations.

Small Details Make Big Differences

Subtle adjustments in joint tension and tension wire placement can transform a stiff figure into one that moves with lifelike fluidity. I wish I had paid more attention to these nuances from the start, as they truly elevate the realism of the doll’s movements.

Iterative Testing is Essential

Creating prototypes and testing their articulation repeatedly is vital. I used to rush the process, but now I understand that patience and iterative refinement lead to the best results. This approach has helped me craft dolls with unparalleled expressiveness.

Embedding Mechanical Systems Seamlessly

Integrating miniature gears and tension wires without compromising the aesthetic appeal is a complex art. I learned that meticulous planning and clean craftsmanship are key to achieving seamless, functional joints that look as good as they move.

Resources I’ve Come to Trust Over Time

- Craftsy’s Doll-Making Tutorials: These tutorials provide detailed guidance on joint design and material usage, which have been invaluable for me.

- Instructables: A treasure trove of user-generated projects showcasing innovative doll articulation techniques that inspire creativity and problem-solving.

- Research Papers on Biomechanics: For understanding human joint mechanics, academic papers have deepened my appreciation of natural movement and how to replicate it in miniature.

- Community Forums: Engaging with fellow artisans on forums has allowed me to share insights, troubleshoot issues, and stay motivated throughout my journey.

Parting Thoughts from My Perspective

Mastering complex doll articulation is both challenging and incredibly rewarding. It’s a perfect blend of art, engineering, and patience. From understanding the delicate balance of joint tension to seamless material integration, every step pushes your skills further. I encourage anyone passionate about doll sculpting to dive deep into these techniques — the results are truly breathtaking. If this resonated with you, I’d love to hear your thoughts or experiences. Feel free to share your journey in the comments or pass this along to a fellow artist who might find it helpful. Remember, every doll you create is a step toward mastery and personal expression, so enjoy every moment of the process.