My Journey into Damascus Steel Crafting: A Personal Tale

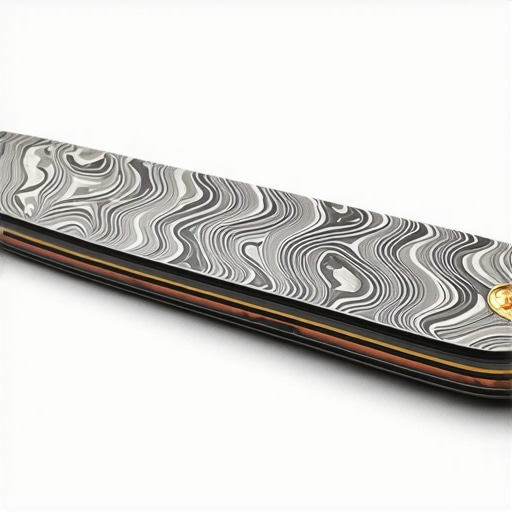

As someone fascinated by the art of metalworking, I vividly remember the first time I held a Damascus steel piece—it felt like holding history itself. The intricate patterns and the legendary strength of Damascus steel have always captivated me. When I decided to craft a Damascus steel letter opener as a gift for a fellow steel enthusiast, I knew I was embarking on a rewarding journey that combined tradition, craftsmanship, and personal touch.

Discovering the Art of Damascus Steel: More Than Just a Steel Type

Damascus steel isn’t just a material; it’s an art form. Its distinctive wavy patterns are created through a complex process of forging multiple layers of steel and iron. Over the years, I’ve learned that the beauty of Damascus lies in both its visual appeal and its legendary durability. To get started, I studied reputable sources like advanced metalworking techniques to understand the nuances of forging, pattern-welding, and heat treatment.

My Personal Process: From Raw Materials to a Masterpiece

Creating a Damascus steel letter opener involves several meticulous steps. I began with high-quality steel rods, carefully selecting those with the right carbon content for optimal pattern formation. After heating the steel to a specific temperature, I repeatedly forged and folded the layers, which created the mesmerizing patterns unique to Damascus steel. The process required patience and precision, but the satisfaction of seeing the patterns emerge was unparalleled. Finishing involved careful polishing and sharpening, turning a rough forged piece into a sleek, functional art piece.

Why a Damascus Steel Letter Opener Makes a Perfect Gift

In my experience, a Damascus steel letter opener is more than a tool; it’s a symbol of craftsmanship and tradition. Its aesthetic appeal and functional design make it an ideal gift for collectors and steel lovers alike. When I gifted mine, the recipient’s eyes lit up with admiration—knowing I had personally crafted each pattern made it all the more special. It’s a gift that combines artistry, utility, and a personal story, making it memorable for years to come.

What Makes Damascus Steel So Unique Compared to Other Metals?

Damascus steel’s uniqueness lies in its layered construction and the forging process that creates its stunning patterns. Unlike uniform steels, Damascus’s distinctive visual textures are a testament to the skill involved in its creation. This process not only results in a beautiful product but also enhances the steel’s strength and resilience—qualities highly valued in both historical and modern contexts.

If you’re inspired to craft your own Damascus steel piece or want to explore more about DIY metalworking, I recommend checking out smart DIY ideas for practical tips and tricks. And if you’re curious about the detailed steps involved in pattern-welding, there’s a wealth of tutorials that can guide you through each stage of the forging process.

If you’ve ever crafted or received a Damascus steel item, I’d love to hear your story—share your experiences in the comments below or reach out through our contact page. Crafting with Damascus steel is truly a rewarding experience that connects us to ancient traditions while allowing modern creativity to flourish.

Unlocking the Secrets of Damascus Steel: A Closer Look at Pattern-Welding Techniques

One of the most fascinating aspects of Damascus steel is its intricate patterning, which results from a complex process called pattern-welding. As an experienced craftsman, I’ve found that understanding the nuances of layering different steels is crucial to achieving stunning visual effects and optimal steel properties. The process involves stacking various steel types—each with distinct carbon contents—and repeatedly forge-welding them together. This creates a layered structure that, when etched, reveals the characteristic waves and swirls that define Damascus steel.

How Do Different Steel Types Influence Pattern Formation and Durability?

In my practice, selecting the right combination of steels significantly impacts both the aesthetic and functional qualities of the final piece. For example, high-carbon steels like 1095 are preferred for their hardness and edge retention, while low-carbon steels such as 1018 contribute ductility and ease of forging. The layering ratio and thickness also affect the pattern complexity and the steel’s resilience against chipping or cracking. Consulting specialized resources like advanced metalworking techniques can provide invaluable insights into optimizing these parameters for different applications.

Precision Heat Treatment: The Art of Achieving the Perfect Balance

Beyond forging, heat treatment plays a pivotal role in enhancing Damascus steel’s properties. Proper normalization, annealing, and hardening processes ensure that the layered structure attains the desired hardness while maintaining toughness. I often employ differential tempering—heating specific areas selectively—to create contrast and accentuate the pattern, especially in decorative pieces. Achieving this balance requires meticulous control of temperature and timing, which can be refined through experience and careful monitoring.

What Are the Most Common Pitfalls in Damascus Steel Heat Treatment, and How Can They Be Avoided?

One frequent challenge is over-tempering, which can soften the steel excessively and diminish its edge-holding capability. Conversely, under-tempering may lead to brittleness. To mitigate these issues, I recommend using a reliable thermocouple and practicing incremental heating, checking hardness with a file or microhardness tester. Also, understanding the steel’s specific heat treatment protocols—whether for a culinary knife or a decorative piece—ensures that each application benefits from tailored processes.

Exploring professional tutorials or workshops, such as those offered by seasoned smiths, can deepen your skills in heat treatment and pattern-welding. Remember, the mastery of Damascus steel lies not only in the forging but also in the precise control of every step in the process.

For those interested in elevating their craftsmanship, experimenting with different steel combinations and heat treatment schedules can lead to unique patterns and enhanced material properties. Sharing your progress and challenges in community forums or online groups can accelerate your learning curve and inspire new creative directions. And if you’re eager to take your skills further, consider reaching out to experts or enrolling in specialized courses—many of which can be found through trusted sources like smart DIY ideas.

Reflections on the Complexities of Pattern-Welding in Damascus Steel

As I delved deeper into the art of Damascus steel, I realized that mastering pattern-welding is akin to learning a new language—one that combines precision, patience, and an intuitive understanding of steel behavior. Each layer I forge and fold unlocks a new dimension of creativity, revealing patterns that are as unique as fingerprints. This process is not merely technical; it’s an artistic journey where every twist and turn brings me closer to the intricate beauty that defines Damascus steel.

The Nuances of Steel Selection: Beyond the Basics

One of the most rewarding aspects of my experience has been experimenting with different steel combinations. I found that pairing high-carbon steels like 1095 with softer steels such as 1018 allows for a harmonious balance between durability and flexibility. But the real magic lies in understanding how each steel’s properties influence pattern formation and resilience. Consulting authoritative sources like advanced metalworking techniques has been instrumental in refining my choices, ensuring my patterns are not only stunning but also functionally sound.

Heat Treatment: The Art of Achieving Balance and Depth

Heat treatment remains the most delicate part of my Damascus projects. Achieving the perfect balance between hardness and toughness requires meticulous control over temperature and timing. I often employ differential tempering, heating specific regions to bring out the contrast in patterns. This step demands patience and a keen eye, as even slight deviations can alter the final appearance and performance. Over time, I’ve learned to interpret subtle cues—like the steel’s color or response to touch—that guide me toward optimal results.

Deepening My Understanding: How Do Advanced Pattern-Welding Techniques Elevate the Craft?

Advanced techniques such as random pattern forging or incorporating contrasting steels with different alloy compositions can dramatically elevate the visual complexity and structural integrity of Damascus steel. These methods push the boundaries of traditional pattern-welding, allowing for more intricate designs that challenge even seasoned smiths. For instance, some artisans experiment with layering stainless steel or exotic alloys to create patterns that shimmer differently when etched, adding a new dimension of depth and sophistication. Exploring resources like advanced metalworking techniques has opened my eyes to these possibilities, inspiring me to innovate and refine my craft further.

Sharing and Growing: The Power of Community and Continuous Learning

One of the most enriching parts of my Damascus journey has been connecting with a community of like-minded craftsmen. Sharing my patterns and techniques not only provides valuable feedback but also sparks new ideas and collaborations. I encourage fellow enthusiasts to document their progress and exchange insights—whether through forums, workshops, or social media. Engaging with experienced smiths and participating in masterclasses has deepened my understanding and pushed me to explore more sophisticated methods.

If you’re passionate about pattern-welding or considering embarking on your Damascus steel journey, I invite you to share your experiences or ask questions—your insights can inspire others. For those looking to expand their skills, exploring detailed tutorials and community projects can be incredibly rewarding. Remember, mastery in Damascus steel is a continuous process of experimentation and reflection, where each new pattern tells a story of perseverance and artistry. Feel free to reach out through our contact page—I’d love to hear about your adventures in this timeless craft.

Refining Pattern-Welding: The Science Behind Complex Layering

As I delved deeper into Damascus steel, I discovered that mastering complex pattern-welding techniques is akin to conducting a symphony of steel layers. Each fold, each weld, contributes to an intricate dance that results in mesmerizing patterns and enhanced structural integrity. The key lies in understanding how different steel alloys interact during high-temperature forge-welding, influencing both aesthetics and durability. For instance, incorporating stainless steel layers introduces a shimmering contrast, elevating visual appeal while preserving corrosion resistance—an approach explored extensively in advanced metalworking literature.

Optimizing Heat Treatment for Artistic Depth and Structural Resilience

Heat treatment remains the cornerstone of my Damascus projects. Achieving the perfect balance between hardness and toughness demands meticulous control over temperatures and timing. Differential tempering, for example, allows me to accentuate the layered patterns, creating a visual depth that highlights the craftsmanship. I often utilize a combination of traditional oil quenching and modern cryogenic processes to refine the microstructure, ensuring resilience against chipping and wear. This nuanced approach echoes the insights shared by metallurgists at specialized workshops, emphasizing that mastery over heat treatment elevates a piece from mere functionality to true artistry.

Can Advanced Pattern-Welding Techniques Create Unique Functional Art?

Absolutely. By experimenting with exotic alloys such as titanium or nickel steels, I have been able to craft Damascus blades with distinctive patterns that are also highly functional. These materials introduce complex visual textures and unique property profiles, pushing the boundaries of traditional pattern-welding. Engaging with community forums and sharing my experiments has been invaluable—fostering innovation and collective learning. If you’re eager to explore these advanced techniques, I recommend immersing yourself in expert tutorials and joining masterclasses that focus on alloy experimentation and microstructural analysis. The journey toward creating both beautiful and resilient Damascus steel is ongoing and deeply rewarding.

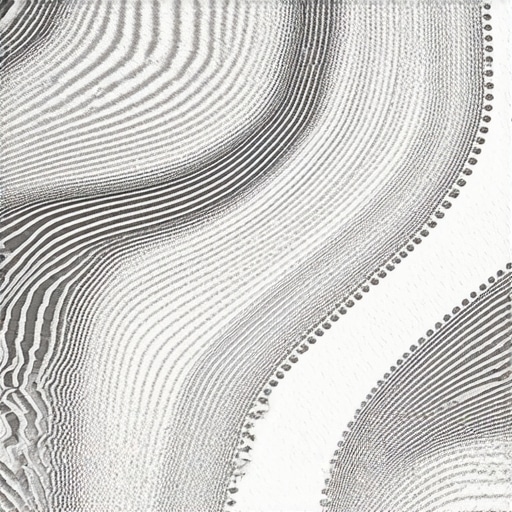

Visualizing the layered complexity of Damascus steel can be inspiring. An image showing a cross-section of layered steel, with contrasting alloys and intricate patterning, can illustrate the depth of craftsmanship involved in advanced pattern-welding techniques.

Innovative Approaches to Achieving Pattern Symmetry and Repetition

One of the challenges I often face is maintaining symmetry in complex patterns. To address this, I employ precise stacking techniques and leverage computer-aided design (CAD) tools to plan layer arrangements before forging. This fusion of traditional craftsmanship with modern technology allows for unprecedented control over pattern repetition, resulting in visually harmonious pieces. Such innovative approaches are documented in detailed guides like metalworking tutorials, which I highly recommend for those seeking to elevate their precision and creativity.

Community and Continuous Innovation: The Heart of Damascus Steel Mastery

Sharing my progress with a community of passionate artisans has been crucial. Online forums and local workshops provide invaluable feedback and inspiration. Engaging with experienced smiths has opened my eyes to new alloy combinations, heat treatment schedules, and pattern techniques that I would not have discovered alone. If you’re committed to mastering Damascus steel, I encourage you to participate actively in these communities and to document your experiments meticulously. Each pattern tells a story of perseverance and innovation, driving us all toward higher levels of craftsmanship. Feel free to reach out through our contact page to share your journey or seek advice on your next project.

Things I Wish I Knew Earlier (or You Might Find Surprising)

The Complexity of Pattern Formation

When I first started forging Damascus steel, I underestimated how intricate the pattern-welding process truly is. It’s not just about stacking steel layers; it’s about understanding how each layer interacts during high-temperature forge-welding. My initial patterns were simple, but with more experience, I discovered that experimenting with different steel alloys can produce astonishingly complex designs that tell a story of craftsmanship and creativity.

The Importance of Precise Heat Control

One of the biggest surprises for me was how sensitive Damascus steel forging is to temperature. Even a slight deviation can alter the pattern or weaken the final product. I learned to use thermocouples and to monitor the steel’s color carefully, which significantly improved my results. Mastery over heat treatment is truly an art that separates an amateur from a seasoned smith.

Layering Isn’t Just Visual—It’s Structural

Initially, I thought layering was mainly for aesthetic appeal. However, I found that the layered structure actually enhances the steel’s durability and resistance to chipping. This realization motivated me to pay closer attention to the quality of each layer and to refine my forging techniques to strengthen the final piece.

The Role of Patience and Practice

Creating Damascus steel isn’t a quick process; it requires patience and repeated folding, forging, and polishing. I’ve come to appreciate that each pattern is unique and that perfection comes with persistence. This journey has taught me that embracing the learning curve is essential to mastering this beautiful craft.

Unexpected Challenges in Finishing Touches

Polishing and etching reveal the patterns, but achieving clear, sharp designs took me longer than expected. I discovered that using different acids for etching and experimenting with polishing grit levels can dramatically improve the visual contrast. These finishing details truly make or break the artistic impact of Damascus steel.

Resources I’ve Come to Trust Over Time

- Advanced Metalworking Techniques — This website provided me with detailed guides on pattern-welding and heat treatment, helping me understand the nuances of Damascus steel forging. I highly recommend it for anyone serious about learning the craft.

- KnifeMaking.com Forums — An active community of craftsmen sharing tips, troubleshooting, and showcasing their work. It’s a great place to get inspired and ask questions.

- Books on Damascus Steel and Pattern-Welding — Classic texts like “The Art of Damascus Steel” deepened my understanding of historical techniques and modern innovations. They’re invaluable resources for both beginners and advanced smiths.

Parting Thoughts from My Perspective

Forging Damascus steel has been an eye-opening journey that combines patience, science, and artistry. The layered patterns and the strength of the steel are a testament to the beauty of traditional craftsmanship blended with modern techniques. If you’re considering exploring this craft, I encourage you to embrace the learning process, experiment boldly, and enjoy every step of creating something truly unique. If this resonated with you, I’d love to hear your thoughts or experiences—feel free to share in the comments or reach out through our contact page. Happy forging!