My First Encounter with Miniature Steam Engines: A Spark of Curiosity

It all started on a rainy weekend when I stumbled upon a fascinating YouTube video about tiny steam engines. That moment ignited my passion for DIY projects and engineering craftsmanship. I realized that creating my own miniature steam engine from metal stock would be both challenging and incredibly rewarding, merging practical skills with a touch of old-world charm.

Gathering Materials: The First Step into Hands-On Engineering

My journey began with sourcing quality metal stock—copper, brass, and steel rods. I learned that choosing the right materials is crucial for durability and aesthetic appeal. I spent hours at my local metal supplier, guided by the advice of experienced hobbyists, and finally selected pieces that would withstand the rigors of steam pressure while remaining easy to work with. For detailed guidance, I found step-by-step DIY guides invaluable for beginners like me.

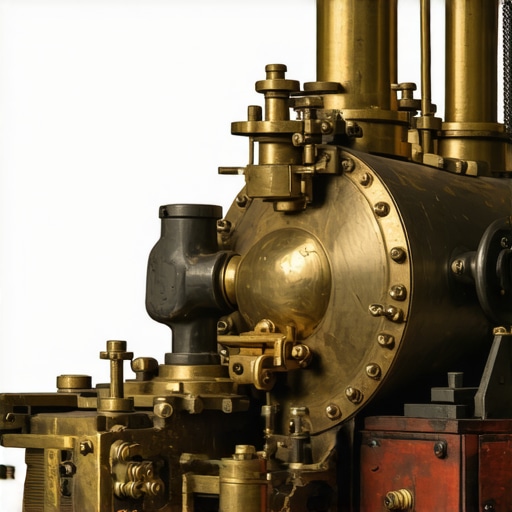

Turning Raw Metal into Engine Parts: My Personal Workshop Experience

Using a combination of hand tools and small power equipment, I started shaping the metal pieces. The process of drilling, sawing, and threading was both meticulous and meditative. I soon discovered that patience and precision are key—rushing can lead to misaligned parts or weak joints. It was during this phase that I appreciated the importance of safety measures, such as wearing goggles and working in a well-ventilated space. As I meticulously assembled the components, I realized that understanding the mechanics behind steam engines—like pistons, cylinders, and valves—enhanced my appreciation for this project. For more advanced techniques, I often referred to advanced DIY solutions.

Assembling the Engine: From Parts to Functioning Model

The moment of truth came when I assembled the parts into a functional miniature steam engine. Testing it was exhilarating; seeing steam gently propel the pistons was a testament to hours of careful craftsmanship. I faced some setbacks—leaks and misfires—but each problem was an opportunity to learn and improve. This hands-on experience taught me more than any textbook could about mechanical systems and the importance of precision engineering. Exploring more about how these engines work, I found creative DIY solutions that can inspire future projects.

Why Building a Miniature Steam Engine Is a Personal Achievement

This project was more than just a hobby; it was a journey into patience, problem-solving, and engineering creativity. Every small success boosted my confidence, and I now see DIY engineering as a rewarding way to connect with the past while honing practical skills. For those curious about venturing into similar projects, I highly recommend exploring upcycling and sustainable DIY ideas to complement your mechanical pursuits.

What’s the most surprising thing you’ve learned from building your own miniature steam engine?

If you’ve ever tried creating something similar or are considering it, I’d love to hear your experiences. Sharing tips and stories helps us all grow in our DIY endeavors. Feel free to leave a comment below or explore more about DIY projects on my blog!

Unlocking Mechanical Mastery: The Art of DIY Miniature Steam Engines

Creating a miniature steam engine is more than just assembling tiny metal parts; it is a journey into the depths of mechanical engineering and craftsmanship. With each component, from the piston to the cylinder, you delve deeper into understanding how these fascinating machines operate. This project not only enhances your technical skills but also connects you with a rich history of industrial innovation. For a comprehensive guide on tackling complex DIY projects, visit step-by-step DIY guides.

Designing Your Miniature Powerhouse: From Concept to Blueprint

Before you dive into metalwork, the design phase is crucial. Drawing precise sketches and detailed blueprints ensures that each part fits perfectly and functions smoothly. Consider the size constraints and the materials you’ll use—brass and copper are popular choices for their workability and aesthetic appeal. Engaging with expert resources such as advanced DIY solutions can inspire innovative design techniques and precision craftsmanship.

Fabricating Components: Precision, Patience, and Practice

Shaping metal parts requires a combination of hand tools and small power tools. Techniques like drilling, threading, and soldering demand meticulous attention to detail. Ensuring accurate measurements and alignment prevents leaks and mechanical failures. Remember, safety gear is essential—goggles and gloves protect against accidental injuries. The process of fabricating these tiny parts deepens your understanding of mechanical linkages and thermodynamics principles. For further insights into advanced fabrication methods, explore advanced DIY techniques.

Assembly and Testing: From the Workshop to the World

Assembling the engine involves careful fitting and alignment of each component. The first test run is always exciting; watching steam power the pistons is a rewarding moment. Expect some setbacks—leaks or misfires are common at this stage—but these challenges are invaluable learning opportunities. Troubleshooting such issues sharpens your problem-solving skills and understanding of steam dynamics. For those interested in expanding their mechanical projects, I recommend exploring creative DIY solutions for inspiration.

The Significance of Handcrafting Mechanical Models for Enthusiasts

Building a miniature steam engine is a profound exercise in patience and precision. It exemplifies how detailed craftsmanship can bridge the gap between historic engineering and modern DIY innovation. Every successful test run fuels confidence and stimulates creative thinking. Moreover, engaging in such projects fosters an appreciation for the mechanical ingenuity that powered the industrial revolution. For eco-conscious makers, integrating sustainable practices like upcycling materials can complement your mechanical pursuits and promote environmental responsibility.

What are the most intricate challenges you’ve faced while building miniature mechanical devices, and how did you overcome them?

If you have experience with similar projects or are considering starting one, sharing your insights can inspire others. Feel free to leave a comment or explore more DIY ideas on my blog to deepen your craftsmanship journey!

Reflections on the Intricacies of Crafting Miniature Steam Engines

Building a miniature steam engine is an endeavor that challenges both patience and precision, demanding a deep understanding of mechanical principles and meticulous craftsmanship. Over time, I’ve come to appreciate the delicate balance between artistry and engineering, where each tiny component must fit perfectly to ensure smooth operation. One of the most surprising lessons I learned was how small misalignments could cause significant performance issues, highlighting the importance of careful measurement and alignment during assembly. This experience deepened my respect for historic engineering marvels, inspiring me to incorporate sustainable materials, such as reclaimed metals, into future projects, aligning craftsmanship with eco-conscious practices.

Delving Into Advanced Techniques and Overcoming Complex Challenges

As I advanced in my projects, I explored sophisticated fabrication methods, including micro-soldering and precision threading, which are crucial for creating reliable, leak-proof joints. These techniques demand a steady hand and an eye for detail, often requiring specialized tools and a controlled environment. For instance, mastering advanced DIY solutions has enabled me to design custom parts with intricate patterns, elevating the aesthetic appeal of my models. Challenges such as steam leaks or piston misfires are inevitable, but troubleshooting them has become a rewarding puzzle—each fix enhances my understanding of thermodynamics and fluid dynamics.

Engaging with the Community and Sharing Deeper Insights

One of the most enriching aspects of this hobby is connecting with a community of passionate creators. Sharing insights about overcoming intricate challenges, like aligning tiny gears or sealing delicate joints, fosters a collaborative environment where ideas flourish. I encourage fellow enthusiasts to document their process and exchange tips—perhaps through detailed blog posts or forum discussions. For example, exploring creative DIY crafts can inspire innovative approaches to traditional engineering projects. If you’ve faced similar challenges or have unique solutions, I’d love to hear your stories—drop a comment below or share your experiences on my blog!

Incorporating Personal Philosophy Into Mechanical Craftsmanship

Beyond technical mastery, I view miniature steam engines as a form of artistic expression—tiny sculptures that embody both history and innovation. This perspective encourages me to experiment with different materials and design philosophies, blending old-world charm with modern sustainability. As I continue to refine my skills, I aim to push the boundaries of what’s possible in small-scale mechanical modeling, perhaps integrating electronic controls or automation, blurring the line between traditional craftsmanship and modern technology. This ongoing journey not only enhances my technical prowess but also nurtures a deeper appreciation for the artistry involved in mechanical design.

Refining Precision: The Art of Microfabrication and Its Challenges

Delving deeper into the realm of miniature steam engines requires mastery over microfabrication techniques, such as micro-soldering and ultra-fine threading. These skills are essential for creating leak-proof joints and ensuring mechanical reliability at a tiny scale. I’ve found that investing in high-quality, precision tools and maintaining a controlled environment significantly enhances the quality of my work. For instance, employing a micro-torch with adjustable flame allows for delicate soldering, minimizing thermal stress on small components. Overcoming challenges like steam leaks or piston misalignments demands a meticulous approach, often involving iterative testing and incremental adjustments. This process has deepened my understanding of fluid dynamics and thermal expansion at micro scales, aligning with insights shared by experts like academic research on microfabrication techniques. Such advanced skills elevate DIY projects from basic assembly to professional craftsmanship, making each successful build a testament to precision engineering.

Integrating Modern Technology with Traditional Craftsmanship

While my passion lies in handcrafted mechanical models, I recognize the value of integrating modern technology to push creative boundaries. For instance, incorporating tiny electronic sensors and microcontrollers can automate operations or enhance control systems within miniature engines. This fusion of old-world craftsmanship and new tech not only broadens functional possibilities but also offers educational opportunities for enthusiasts eager to learn integrated systems. I’ve experimented with Arduino-based controls to regulate steam pressure or automate start-up sequences, seamlessly blending mechanical ingenuity with programming. Exploring smart DIY solutions has provided invaluable insights into such integrations. This approach encourages a multidisciplinary perspective, fostering innovation that respects traditional skills while embracing technological advancements.

What Are the Most Effective Strategies for Achieving Precision in Miniature Engineering Projects?

If you’re venturing into complex miniature mechanical builds, I highly recommend adopting a systematic approach to measurement and assembly. Using digital calipers, dial gauges, and magnification tools ensures accuracy at every stage. Moreover, maintaining a detailed journal of adjustments helps track progress and refine techniques over successive iterations. Engaging with community forums and expert tutorials can provide fresh perspectives; for example, detailed guides on advanced DIY design can inspire precision in component fabrication. Sharing your experiences and troubleshooting strategies not only accelerates learning but also enriches the collective knowledge of the DIY community. I invite you to explore more about these advanced methods and share your own insights—collaborative learning is essential in mastering such intricate crafts.

Unlocking the Potential of Sustainable and Eco-Conscious Crafting

Sustainable practices are increasingly vital in all DIY pursuits. In my projects, I prioritize upcycling reclaimed metals and environmentally friendly materials whenever possible. For example, sourcing scrap brass or recycled copper not only reduces environmental impact but also adds character to the finished model. Integrating eco-conscious methods aligns with broader efforts to promote responsible craftsmanship, as discussed in resources like upcycling initiatives. This philosophy encourages innovation within ecological boundaries, inspiring projects that are both technically impressive and environmentally responsible. As I continue to refine my techniques, I challenge myself to find new ways to balance mechanical precision with sustainable materials, fostering a more conscious approach to craftsmanship that I believe benefits both the environment and the craft itself.

Mastering DIY Miniature Steam Engines: Tips, Resources, and Personal Insights

Reflecting on my journey into creating miniature steam engines, I realize how much more there is to discover beyond the basic steps. Building these tiny marvels has been a rewarding blend of creativity, patience, and technical skill. If you’re passionate about DIY engineering or just curious about this intricate craft, I hope my insights help you along your own path.

Things I Wish I Knew Earlier (or You Might Find Surprising)

Small Details Make a Big Difference

One of the most surprising lessons I learned was how tiny misalignments could cause significant performance issues. Precision in measurement and assembly is crucial, and overlooking small details can lead to leaks or mechanical failures.

Materials Matter More Than You Think

Choosing the right metals like brass or copper not only impacts durability but also affects how easily you can work with them. I underestimated how much the material’s properties influence the crafting process and the final outcome.

Patience Is a Virtue in Microfabrication

Techniques such as micro-soldering require a steady hand and a calm mind. Rushing through these steps can ruin delicate parts, so taking your time really pays off in the quality of your engine.

Community Support Accelerates Learning

Engaging with online forums and trusted resources like step-by-step DIY guides has been invaluable. Sharing experiences and troubleshooting tips with fellow enthusiasts keeps motivation high.

Sustainability Enhances Creativity

Incorporating recycled metals and eco-friendly practices not only benefits the environment but also adds character to my projects. Upcycling old materials has opened new avenues for creative expression and responsible craftsmanship.

Resources I’ve Come to Trust Over Time

- DIY Guides on DIYKUTAK: An extensive collection of detailed, beginner-friendly instructions that cover a wide range of projects, including miniature engines, making it my go-to resource.

- ScienceDirect: For understanding the scientific principles behind steam and thermodynamics, this platform offers peer-reviewed articles that deepen my technical knowledge.

- Instructables: A community-driven site filled with innovative ideas and step-by-step tutorials that inspire new techniques and project ideas.

- Maker Forums: Engaging with fellow hobbyists through forums helps me troubleshoot and learn from others’ experiences, fostering a sense of community.

Parting Thoughts from My Perspective

Creating a miniature steam engine has been a journey of patience, learning, and personal growth. It’s incredible how small components and meticulous craftsmanship come together to produce a functional model that echoes the ingenuity of industrial pioneers. I encourage anyone interested in this craft to explore resources like advanced DIY solutions and embrace the process, imperfections and all. If this resonated with you, I’d love to hear your thoughts or stories about your own DIY adventures. Sharing our experiences helps us all grow and keeps the passion alive. Feel free to drop a comment or explore more inspiring projects on my blog!