Igniting Passion: The Art and Science Behind Miniature Steam Engines

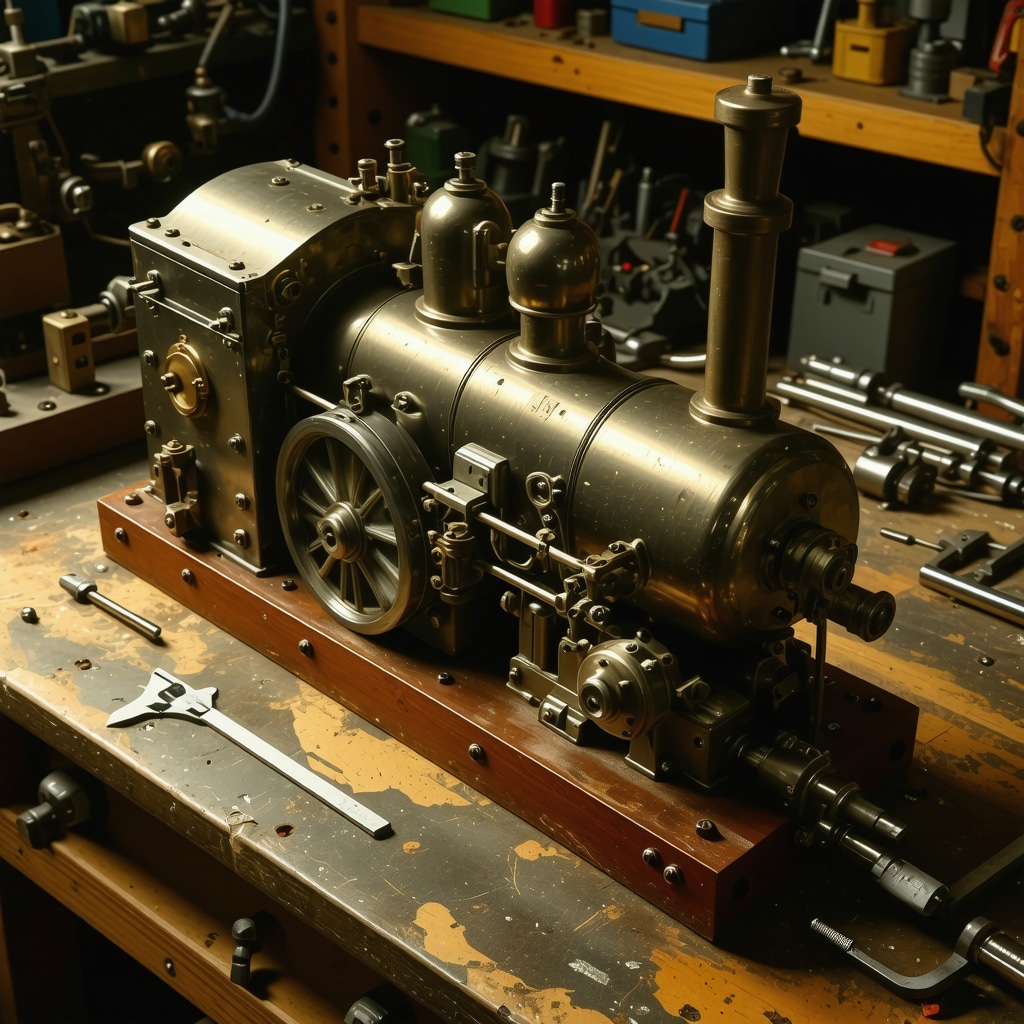

Building a functional miniature steam engine is more than a hobby—it’s an intricate dance between physics, precision metalwork, and craftsmanship. For enthusiasts and skilled DIYers alike, this project epitomizes how mechanical ingenuity can be distilled into a compact, operable marvel. The process demands meticulous attention to detail, a deep understanding of materials, and patience to transform raw metal into a living, breathing engine. This guide explores the essential steps for crafting your own steam engine, unraveling the metalwork secrets that breathe life into this timeless machine.

Forging the Heart: Precision Metalwork Techniques for Engine Components

At the core of every miniature steam engine lies the boiler, cylinder, piston, and valve system—each requiring precise metal shaping and fitting. Begin with selecting metals like brass or stainless steel, prized for their durability and heat resistance. Using a lathe, craft the cylindrical boiler with exact tolerances to safely contain steam pressure. Milling the piston and cylinder demands micrometer-level precision to ensure smooth reciprocating motion without steam leakage. Expert use of files and drills for valve ports and steam passages is critical; even minor imperfections can disrupt performance. Embracing techniques such as silver soldering or TIG welding can join components seamlessly, preserving both strength and aesthetic integrity. Drawing from practical experience, the key is to maintain strict dimensional control and finish surfaces to minimize friction—skills that separate a functional engine from a mere model.

Mastering the Steam Cycle: How Does a Miniature Steam Engine Work?

The working principle of your miniature engine hinges on steam pressure converting thermal energy into mechanical motion. Water heated within the boiler turns into steam, which expands and pushes the piston inside the cylinder. This linear piston motion is transformed into rotary motion via a connecting rod and crankshaft, driving the engine’s flywheel. Valves meticulously timed to open and close allow steam to enter and exhaust at precise intervals, optimizing efficiency. Understanding this steam cycle is vital to metalwork choices: for example, valve seat surfaces must be ground finely to prevent leaks, and piston rings crafted to maintain a tight seal without excessive friction. This interplay between design and metalwork embodies the craftsmanship that enthusiasts cherish.

Tools of the Trade: Essential Equipment for Your Metalworking Workshop

Building a miniature steam engine demands a well-equipped metal shop. Beyond the basics like a lathe, milling machine, and drill press, precision measuring tools such as micrometers, dial indicators, and calipers are indispensable for achieving tight tolerances. Fine files, deburring tools, and metal polishers ensure smooth finishes that enhance performance. For joining parts, a silver soldering setup or TIG welder offers clean, reliable bonds. Investing in quality cutting oils and abrasives will prolong tool life and improve the quality of cuts. Seasoned builders often customize their workspace to optimize workflow and safety, recognizing that an organized environment underpins successful metalwork projects.

What Are Common Challenges When Building a Miniature Steam Engine and How to Overcome Them?

One of the primary challenges is achieving airtight seals in tiny components, where even microscopic gaps cause steam loss and reduced power. Employing high-precision machining and meticulous surface finishing minimizes these issues. Another difficulty lies in managing thermal expansion; selecting compatible metals and allowing for expansion in design prevents binding or cracks. Additionally, balancing aesthetics with function can be tricky—excessive polishing may thin critical parts, while rough finishes increase wear. Experienced builders recommend iterative testing and adjustment, embracing patience as a virtue. Consulting resources like the Model Engine Maker community offers invaluable insights and peer support to navigate these complexities.

Fueling Your Creativity: Dive Deeper Into DIY Metalwork and Engineering

Ready to expand your metalworking prowess beyond steam engines? Explore comprehensive step-by-step DIY guides that cultivate skills for diverse projects. Whether crafting kinetic sculptures or custom workshop tools, mastering these techniques elevates your craftsmanship. Share your miniature steam engine journey or ask questions in the comments to connect with fellow enthusiasts and refine your art.

Refining Precision: Advanced Techniques to Perfect Your Miniature Steam Engine

With foundational metalworking skills established, advancing to finer precision techniques is essential to elevate your miniature steam engine’s performance and reliability. Techniques such as lapping and honing the cylinder bores ensure ultra-smooth surfaces that minimize friction and wear, thereby extending the engine’s operational lifespan. Utilizing surface grinders to achieve flatness on valve seats enhances sealing efficiency, critical for maintaining optimal steam pressure. Additionally, heat treating certain metal components can improve hardness and resistance to deformation under thermal cycling. These refinements demand patience and a meticulous approach but yield engines that not only function better but also stand out as showcases of craftsmanship.

Material Innovations: Selecting Alloys for Durability and Efficiency

While traditional brass and stainless steel remain popular, modern alloy options can offer superior properties for miniature steam engines. For instance, phosphor bronze provides excellent wear resistance and low friction, ideal for bushings and bearings. Aluminum alloys, when properly anodized, reduce weight without compromising strength, which can enhance the responsiveness of moving parts. However, compatibility with steam and heat exposure must be carefully evaluated to avoid corrosion or fatigue failures. Consulting material datasheets and experimenting with small sample components helps builders make informed choices that balance cost, machinability, and durability.

How Can CNC Machining Enhance the Crafting of Miniature Steam Engines for Precision and Repeatability?

Computer Numerical Control (CNC) machining introduces a new level of precision and repeatability to miniature steam engine fabrication. CNC mills and lathes can produce complex geometries with micrometer accuracy, drastically reducing human error inherent in manual machining. This technology allows for consistent production of parts such as pistons, cylinders, and valve components, ensuring perfect fits and smoother operation. Moreover, CNC enables the creation of intricate patterns and custom designs otherwise difficult to achieve by hand. While the initial investment in CNC equipment and programming skills is substantial, the long-term benefits in quality and efficiency make it a compelling choice for advanced hobbyists and small-scale manufacturers. For an in-depth technical perspective, the Machine Design journal offers authoritative insights on integrating CNC in precision engineering.

Ensuring Safety and Maintenance: Best Practices for Long-Term Engine Health

Safety considerations are paramount when working with steam under pressure, even at miniature scales. Incorporating pressure relief valves and conducting regular inspections for metal fatigue or corrosion can prevent hazardous failures. Additionally, maintaining lubrication on moving parts with appropriate oils reduces wear and heat buildup. Periodic disassembly for cleaning steam passages and checking valve integrity ensures consistent performance. Builders should also document their work and modifications, aiding troubleshooting and future improvements. Adhering to these best practices reflects the professionalism that hallmark expert metalworkers.

Expand your skills further by exploring our step-by-step DIY guides for all skill levels or dive into innovative smart DIY solutions for modern living to apply precision metalwork in diverse projects. Share your experiences or questions in the comments to enrich our community’s collective expertise.

Micro-Machining Mastery: Unlocking the Potential of Ultra-Precision Finishing Techniques

To transcend the boundaries of ordinary miniature steam engine builds, embracing micro-machining finishing techniques becomes indispensable. Processes like lapping, honing, and superfinishing refine component surfaces to nanometer-scale smoothness, drastically reducing friction and enhancing thermal efficiency. Lapping employs abrasive slurries between two surfaces to achieve unparalleled flatness and smoothness, crucial for valve seats and piston-cylinder interfaces. Honing, using precision stones, corrects minor geometric flaws and imparts crosshatch patterns that retain lubricants effectively, thereby extending component longevity.

Moreover, advanced superfinishing methods such as diamond polishing can push surface roughness down to Ra values below 0.01 micrometers, a feat that dramatically improves steam tightness and mechanical lifespan. These ultra-precise finishes require not only specialized equipment but also a deep understanding of abrasive selection, pressure control, and process timing. For the seasoned builder, mastering these nuances translates to engines that perform with exceptional smoothness and reliability under demanding operational conditions.

Innovative Alloy Engineering: Tailoring Material Properties for Miniature Steam Engines

Beyond conventional metals, the frontier of material science offers tailored alloys engineered for specific mechanical and thermal challenges encountered in miniature steam engines. For example, nickel-based superalloys exhibit remarkable creep resistance and oxidation stability at elevated temperatures, making them ideal for boiler components subjected to cyclic thermal loads. Meanwhile, beryllium copper alloys combine excellent thermal conductivity with non-magnetic and corrosion-resistant properties, perfect for precision valve components requiring minimal thermal distortion.

Integrating these high-performance materials necessitates sophisticated machining protocols due to their hardness and work-hardening tendencies. Additionally, understanding phase transformations and heat treatment responses is critical to prevent microstructural defects that could compromise structural integrity. Consulting detailed material datasheets and peer-reviewed metallurgical research, such as articles from the The Minerals, Metals & Materials Society, can provide invaluable guidance in selecting and processing these advanced alloys, ensuring the miniature engine not only survives but thrives in rigorous operating environments.

How Do Thermal Expansion Coefficients Influence Alloy Pairing in Miniature Steam Engine Assemblies?

Thermal expansion mismatches can be a silent adversary in precision steam engines. Different alloys expand at varying rates when heated, potentially inducing stress, warping, or seal failures. For instance, pairing a stainless steel cylinder with a brass piston without allowance for differential expansion can cause binding or leakage as operating temperatures fluctuate.

To mitigate these issues, engineers must carefully select alloys with compatible coefficients of thermal expansion (CTE) or design compensatory features such as flexible joints or clearance allowances. Advanced simulation tools can predict thermal behavior before fabrication, optimizing alloy pairing for longevity and performance. Such foresight is vital in miniature builds where tolerances are tight and thermal gradients significant.

Integrating Modern Instrumentation: Enhancing Performance Monitoring and Diagnostic Capabilities

Incorporating miniature sensors and instrumentation elevates the traditional steam engine into a smart mechanical system. Embedding micro-thermocouples within the boiler and cylinder walls enables real-time temperature mapping, helping to detect hot spots or uneven heating that could jeopardize engine safety and efficiency. Similarly, installing micro-pressure transducers allows continuous monitoring of steam pressure, ensuring operation within safe parameters and facilitating early detection of leaks or blockages.

These data-rich insights empower builders to fine-tune valve timing, steam admission, and exhaust phases with unprecedented precision. Moreover, coupling sensors with microcontrollers and IoT interfaces can automate logging and alert systems, heralding a new era of miniature steam engine experimentation and optimization. For detailed implementation strategies, consult specialized engineering resources such as the IEEE Xplore Digital Library.

Ready to push your miniature steam engine craftsmanship into the realm of advanced engineering? Dive deeper into precision finishing methods and innovative materials to craft engines that are not only functional but also exemplars of mechanical artistry. Share your experiences and questions with our expert community to unlock collective knowledge and elevate your projects further.

Precision Microfabrication: Elevating Miniature Steam Engine Performance Through Nanometric Finishing

Delving deeper into microfabrication, the application of nanometric finishing techniques such as ultra-fine lapping and superfinishing transcends traditional machining limits. These methods achieve surface roughness values in the sub-micrometer range, dramatically reducing frictional losses and wear within critical engine interfaces like piston-cylinder assemblies and valve seats. Such refinement is paramount for sustaining efficiency and operational longevity, especially under frequent thermal cycling and steam pressure fluctuations. Expert practitioners leverage controlled abrasive slurry compositions and meticulously regulated pressure applications to master these finishes, which require both specialized tooling and extensive experiential knowledge to implement effectively.

Strategic Alloy Combinations: Mitigating Thermal Stress Through Material Science Innovations

Incorporating strategic alloy pairings tailored to minimize differential thermal expansion is instrumental in preserving assembly integrity. Utilizing computational thermomechanical simulations enables identification of compatible alloy couples that harmonize coefficients of thermal expansion (CTE), thus preventing stress-induced distortions or seal failures during temperature transitions. For example, pairing nickel-based superalloys with phosphor bronze components can balance robustness and thermal stability. Advanced design approaches also introduce compliant interface materials or micro-gap allowances, serving as buffers to accommodate expansion disparities without compromising mechanical precision.

Embedding Intelligent Instrumentation: Transforming Miniature Steam Engines Into Smart Systems

Integrating micro-electromechanical systems (MEMS) sensors and IoT-enabled data acquisition modules revolutionizes engine diagnostics and performance optimization. Real-time telemetry from embedded micro-thermocouples and pressure transducers facilitates dynamic monitoring of thermal gradients and steam pressure cycles, furnishing actionable insights to refine valve actuation timing and combustion efficiency. Coupling this sensory data with machine learning algorithms can predict maintenance needs, preempt component wear, and automate adaptive control strategies, thus elevating miniature steam engines from static mechanical constructs to sophisticated cyber-physical systems.

How Can Advanced Simulation and Sensor Fusion Improve the Reliability of Miniature Steam Engines in Variable Thermal Environments?

Advanced multiphysics simulation platforms, when integrated with sensor fusion techniques, enable holistic analysis of thermal, mechanical, and fluid dynamic interactions within miniature steam engines. By synthesizing data from distributed sensors with predictive models, engineers can preemptively identify potential failure modes caused by thermal stresses or steam flow irregularities. This proactive approach facilitates real-time adjustments to operating parameters, ensuring consistent performance despite fluctuating environmental conditions. Furthermore, sensor fusion aids in isolating anomalous behavior indicative of micro-leaks or material fatigue, thus extending engine lifespan and operational safety.

For a comprehensive exploration of precision machining combined with digital monitoring, the Machine Design journal offers authoritative articles on integrating CNC machining with smart instrumentation in precision engineering contexts.

Embrace these advanced methodologies to transcend conventional miniature steam engine craftsmanship. Engage with our expert community to share insights, troubleshoot complex challenges, and collaboratively pioneer innovations in micro-mechanical engineering.

Frequently Asked Questions (FAQ)

What metals are best suited for building miniature steam engines and why?

Brass and stainless steel are traditional favorites due to their excellent machinability, corrosion resistance, and heat tolerance. Brass offers ease of shaping and good thermal conductivity, making it ideal for boilers and fittings. Stainless steel provides superior strength and corrosion resistance under steam environments. Advanced alloys such as phosphor bronze and nickel-based superalloys are also used for their wear resistance and thermal stability, especially in bearing and high-temperature components.

How critical is precision machining for the performance of a miniature steam engine?

Precision machining is vital. Tight tolerances ensure airtight seals, smooth piston-cylinder interaction, and efficient valve operation, directly affecting power output and reliability. Imperfections can cause steam leaks, increased friction, and mechanical binding. Techniques like CNC machining, lapping, and honing help achieve the micrometer-level accuracy necessary for high performance and longevity.

How do thermal expansion differences between metals affect miniature steam engine assemblies?

Different metals expand at varying rates when heated, which can induce stresses, warping, or seal failures if not accounted for. Selecting alloys with compatible coefficients of thermal expansion or incorporating design allowances such as flexible joints or clearance gaps mitigates these issues, maintaining assembly integrity and smooth operation despite temperature changes.

Can modern instrumentation be integrated into miniature steam engines?

Yes, embedding micro-thermocouples, pressure transducers, and IoT-enabled sensors transforms the engine into a smart system. These instruments provide real-time monitoring of temperature and pressure, enabling performance optimization, predictive maintenance, and enhanced safety through automated alerts and data logging.

What advanced finishing techniques improve miniature steam engine efficiency?

Micro-machining techniques such as lapping, honing, and superfinishing reduce surface roughness to nanometer scales, minimizing friction and wear in piston-cylinder interfaces and valve seats. Diamond polishing can achieve surface finishes below 0.01 micrometers Ra, dramatically improving steam tightness and mechanical lifespan.

Is CNC machining worth the investment for hobbyists building miniature steam engines?

For serious hobbyists or small-scale producers, CNC machining offers unparalleled precision and repeatability, reducing human error and enabling complex geometries. Although initial costs and learning curves are significant, the quality improvements and ability to produce consistent parts justify the investment for advanced projects.

What safety practices should be followed when operating miniature steam engines?

Incorporate pressure relief valves and perform regular inspections for corrosion or metal fatigue. Maintain adequate lubrication to reduce wear and heat buildup, and periodically clean steam passages and check valve integrity. Document modifications and repairs to facilitate troubleshooting and uphold safe operation.

How do strategic alloy combinations help mitigate thermal stress?

Strategic pairing of alloys with similar thermal expansion coefficients and complementary mechanical properties reduces internal stresses caused by temperature fluctuations. Using compliant interface materials or micro-gap allowances further absorbs expansion differences, preventing distortion and seal failures.

What role do advanced simulations play in miniature steam engine design?

Multiphysics simulations combined with sensor data fusion enable comprehensive analysis of thermal, mechanical, and fluid dynamic interactions. This predictive modeling allows engineers to anticipate failure modes, optimize operating parameters in real time, and extend engine lifespan by mitigating thermal stresses and steam flow irregularities.

How can beginners start learning metalworking for miniature steam engines?

Start with foundational metalworking skills such as lathe and milling machine operation, precision measuring, and soldering. Follow detailed DIY guides and engage with communities like Model Engine Maker for peer support and practical advice. Gradually progress to advanced techniques like honing and CNC programming as proficiency grows.

Trusted External Sources

- The Minerals, Metals & Materials Society (TMS): Provides in-depth metallurgical research and datasheets essential for selecting and processing advanced alloys used in miniature steam engines.

- Machine Design Journal: Offers authoritative articles on precision CNC machining and microfabrication techniques critical for achieving high manufacturing standards.

- IEEE Xplore Digital Library: A premier resource for cutting-edge research on sensor integration, micro-electromechanical systems (MEMS), and IoT applications enhancing miniature steam engine instrumentation.

- Model Engine Maker Community: A specialized forum where experienced builders share practical insights, troubleshooting tips, and project plans tailored to miniature steam engines.

- DIY Kutak: Comprehensive step-by-step DIY guides that develop metalworking and engineering skills applicable to building and refining miniature steam engines.

Conclusion

Crafting a miniature steam engine is a sophisticated blend of meticulous metalworking, material science, and innovative engineering. Mastery over precision machining, advanced finishing techniques, and strategic alloy selection enables builders to create reliable, high-performance engines that honor this timeless technology. Integrating modern instrumentation further propels these mechanical marvels into the era of smart systems, enhancing diagnostics and operational safety. Whether you are a passionate hobbyist or an aspiring expert, embracing these comprehensive insights and techniques will elevate your craftsmanship and deepen your appreciation of miniature steam engines. Share your experiences, explore related expert content, and continue pushing the boundaries of this fascinating engineering art.

The intricate balance of precision and creativity in building miniature steam engines always fascinates me. I appreciate how this post highlights not just the technical skills like machining and soldering but also the deeper understanding of materials and thermal dynamics needed to bring a tiny but functional engine to life. From my own attempts, achieving airtight seals was the toughest hurdle — even the smallest imperfections led to disappointing steam leaks. I found that investing extra time into surface finishing and iterative testing really made the difference. The mention of integrating modern sensors to monitor performance is intriguing too—it’s exciting to think how traditional craftsmanship can evolve with smart technology.

One thing I’ve been curious about is how others manage to balance the aesthetic demands without compromising the mechanical integrity, especially when polishing delicate parts that must withstand thermal stresses. Does anyone have tips on maintaining durability while also giving the engine that polished, museum-quality finish? It seems like a fine line to tread between form and function in such a compact design. I’d love to hear how fellow builders approach this challenge or any tricks they’ve learned along the way.

Maxine, your point about balancing aesthetics with mechanical integrity really resonates with my experience. In my builds, I’ve found that the key is to start with the mechanical essentials—especially precision in the piston and valve areas—before moving onto polishing. Using a fine but controlled polishing technique like micro-abrasive pads helps maintain dimensional tolerances while improving surface finish. Also, I usually avoid aggressive polishing on thinner parts to prevent compromising their strength, opting instead for selective polishing of visible components.

Regarding thermal stresses, I’ve experimented with applying a thin layer of heat-resistant clear coating after polishing to protect surfaces without interfering with fit or function. It seems to provide a nice compromise, preserving the polished look and adding some durability.

Another tip is to frequently test-fit components during finishing stages, ensuring no unintended warping or fitting issues develop. It demands patience but saves headaches later.

I’d be interested to hear if others have tried similar methods or have alternative strategies for achieving that flywheel shine without risking steam-tightness or mechanical performance. Also, how do advanced builders integrate modern sensor tech without detracting from the engine’s classic aesthetic?

Oliver, your insights on balancing polishing with mechanical integrity are really helpful. From my experience, especially when working on the valve seats and piston assemblies, I’ve found that focusing on precision machining first sets the foundation for a durable engine. When it comes to surface finishing, I use a combination of honing for functional areas and gentle hand-polishing for more aesthetic parts. One thing I learned the hard way was that aggressive polishing on functional cylinder surfaces can lead to premature wear and reduced steam efficiency.

Regarding modern sensor integration, I recently experimented with embedding micro-pressure sensors within the boiler casing, concealed under a thin brass cap. This way, the sensors don’t detract from the engine’s classic look but still offer real-time performance data. Using flexible, fine wiring and transparent protective coatings helped keep the traditional appearance intact.

On another note, has anyone tried combining traditional metalworking with 3D printed jigs or fixtures to improve the repeatability and precision during assembly? I imagine this could be a real game-changer for maintaining tight tolerances while managing the complexity of these tiny components. Would love to hear if others have blended old-school craftsmanship with modern tools in their builds!

I really appreciated the comprehensive overview of precision metalwork and the importance of material choice, especially how it impacts the thermal behavior of miniature engines. From my own experience, especially with brass and phosphor bronze, understanding their expansion rates is vital in avoiding leaks or mechanical bind as the engine heats and cools repeatedly. One aspect I’ve explored is the use of flexible metal joints and micro-gaps that accommodate slight movements and reduce stress on seals—it’s a delicate balance but pays off in durability.

The advanced finishing techniques, like lapping and superfinishing, are game changers for achieving smooth surfaces that significantly cut down friction. For hobbyists looking to incorporate modern sensors, I’d recommend starting with off-the-shelf compact modules and carefully plan wiring routes to minimise impact on the aesthetic. Proper insulation and heat-resistant coatings are also critical. Have others found particular sensor brands or configurations that work especially well without compromising the engine’s traditional look? I believe integrating these smart features opens new frontiers for even the most seasoned model engineers.

I really enjoyed the detailed insights on micro-machining and material selection—it’s clear that these details make a huge difference in the longevity and performance of miniature steam engines. From my own experience, I’ve found that incorporating micro-honing after initial turning can really smooth out cylinder bores without risking damage to the parts. It’s an approach that’s worked well for me in maintaining the tight clearances needed for airtight seals, especially when working with brass.

Regarding the integration of sensors, I’ve been experimenting with tiny thermocouples connected to a basic Arduino setup tucked away inside a custom-made housing. The key for me was choosing flexible wiring and using heat-resistant coatings, just like the post discusses. This way, I get real-time data without compromising the vintage look. Has anyone else found that integrating such tech enhances troubleshooting during testing phases? Or do you think it might detract from the aesthetic charm of traditional models? Would love to hear some practical tips on balancing modern diagnostics with craftsmanship.

What an inspiring deep dive into the intricacies of miniature steam engines! I recently completed my first build, and I was struck by how much attention to detail is needed to ensure both performance and longevity. The section on micro-machining and surface finishing really resonated with me, especially the use of honing and lapping to achieve smooth bore surfaces. I found that even small improvements in surface finish dramatically reduced frictional losses and improved the engine’s efficiency.

In my projects, I’ve started experimenting with heat-resistant coatings on the external surfaces and sealing areas to protect delicate finishes during high-temperature operation. Has anyone here tried anything similar, and if so, what coatings have worked best? It seems that integrating small sensors could be a game changer for real-time diagnostics — I would love to hear about others’ experiences with embedding sensors without affecting the engine’s aesthetic and operational integrity. What are some best practices for wiring and protecting these sensors in such compact spaces? I believe that embracing modern tech while respecting traditional craftsmanship opens exciting possibilities. Keen to hear everyone’s insights!

This post really emphasizes the importance of micro-machining and precise material selection in achieving both durability and efficiency in miniature steam engines. I’ve personally found that honing the cylinder bore after initial turning drastically reduces friction and improves overall performance, especially when working with softer metals like brass. It’s impressive how advanced surface finishing techniques like superfinishing can extend the lifespan of components under thermal cycling conditions. I’ve also started experimenting with embedding tiny temperature sensors inside the boiler for real-time monitoring, but routing the wiring without affecting the engine’s aesthetic is quite challenging. Has anyone else tried integrating such sensors into their models? Using flexible, heat-resistant wiring and discreet placement seems to be the way to go. Would love to hear tips on balancing the modern tech with traditional craftsmanship or tips on sensor selection for small-scale applications.

This post provided impressive detail on the importance of micro-machining and precision in miniature steam engines. From my experience, combining traditional hand-finishing with modern micro-engraving techniques can really elevate the aesthetic appeal without sacrificing functional precision. I’ve found that using small, dedicated jig setups with CNC or 3D-printed fixtures helps maintain consistency when working with tiny components, particularly when handling delicate materials like phosphor bronze or special alloys. Has anyone experimented with such hybrid approaches to improve both the reliability and visual finesse of their builds? I am particularly interested in hearing about innovative ways others have balanced form and function, especially in tight spaces where maintaining seal integrity is critical. Looking forward to exchanging practical tips and ideas on integrating smart diagnostics into these tiny engines.

This comprehensive guide truly captures the delicate craftsmanship involved in miniature steam engines. I recently experimented with using anodized aluminium for some non-pressure parts, which helped reduce weight and manage thermal expansion better. It’s fascinating how nuanced the choice of materials can be—especially when considering long-term durability under repeated thermal cycling. When it comes to achieving airtight seals, I’ve found that micro-honing and proper surface finishing are game changers, as mentioned. Has anyone tried combining these with modern digital pressure gauges embedded discreetly for performance monitoring? I think integrating these sensors could open up new avenues for hobbyists to troubleshoot and optimise performance without sacrificing the classic aesthetic. I would love to hear about your experiences or recommendations on sensor placement, especially in areas prone to thermal expansion or vibration. It’s exciting to see both old-school metalwork techniques and modern tech blending together in this craft!

Building a miniature steam engine truly is a blend of art and science, as the post beautifully outlines. What struck me most is the emphasis on precision metalwork—not just in machining, but also in how materials and thermal effects are managed. From my own projects, I can attest that understanding the interplay between thermal expansion and material selection is crucial. I’ve often faced issues where mismatched metals caused binding after the engine warmed up. Implementing small design clearances and choosing alloys with compatible expansion rates made a remarkable difference.

Also, the article’s take on integrating modern instrumentation fascinates me. Embedding tiny sensors for real-time feedback adds a dimension of control previously unheard of in traditional builds. It makes me wonder: how accessible are these micro-sensors for hobbyists without an electronics background? Does anyone here have experience blending these smart systems effectively in their engines? I’d be curious to know what challenges you’ve faced with sensor placement, wiring, or data interpretation, and how that impacts overall engine reliability.

Lachlan, your curiosity about the accessibility of micro-sensors for hobbyists really hits home. From my experience dabbling in miniature steam engines, sourcing and integrating these tiny sensors can feel daunting at first, especially if you lack a background in electronics. However, the rise of maker communities and affordable microcontroller platforms like Arduino or Raspberry Pi has significantly lowered the barrier. Many hobbyists use off-the-shelf micro-thermocouples and pressure sensors connected to simple data-loggers, which often come with clear guides and forums for troubleshooting.

One challenge I faced was routing sensor wiring in such tight spaces without affecting the engine’s movement or aesthetics. Flexible, thin-gauge wires and careful planning helped me minimize interference. I also insulated sensor components with heat-resistant coatings to protect them against steam and high temperatures, which the post rightly emphasizes as crucial for durability.

I’d be keen to hear how others have tackled the learning curve and physical installation of these instruments. Have you found specific brands or kits that simplify the process? Also, does anyone incorporate software tools to interpret the sensor data effectively for maintenance or performance tuning? Sharing these insights could really help hobbyists looking to bridge traditional craftsmanship with modern tech.

Reading through the post and these insightful comments, I’m reminded of my early days working on miniature steam engines where managing thermal expansion was a steep learning curve. Even minuscule mismatches in thermal expansion between piston and cylinder alloys can cause binding or leaks as the engine heats up, sometimes ruining hours of careful machining. I’ve found that trialing different metal combinations on smaller test pieces helped me grasp how materials behave under heat before committing to critical parts. Equally, incorporating slight clearance allowances in the design, as the post suggests, is invaluable.

On the topic of balancing aesthetics and functionality, I appreciate the ideas shared about selective polishing and protective coatings. In my builds, I favour leaving functional parts with a matte finish after precision machining and only polish the outer-facing components, which reduces wear and risk of thermal degradation. It’s a delicate juggling act, but patience and incremental testing have been my best allies.

I’m curious, though, for those who’ve integrated sensor tech into their engines, especially micro-pressure or temperature sensors: how do you ensure that embedding these additions doesn’t alter the engine’s thermal characteristics or introduce new points of failure? Does anyone have best practices for integrating instrumentation that maintains both mechanical performance and durability over time? It seems like the next big step in miniature steam engineering, but one that must be handled thoughtfully.

Building on the thoughtful points made here about achieving airtight seals and managing thermal expansion, I’ve found that patience and small-scale testing are crucial. Before assembling major components like the piston and cylinder, I machine and test-fit each part multiple times to ensure a near-perfect match, especially because even tiny mismatches can lead to steam leaks or binding as temperatures fluctuate. The post’s emphasis on material selection resonates personally—I prefer starting with brass for ease of machining and then pairing it thoughtfully with stainless or phosphor bronze in areas prone to wear.

Regarding surface finishing, I’ve been experimenting with progressive lapping and honing techniques using finer abrasives after the initial machining. This approach not only reduces friction but also enhances sealing without compromising component thickness, which is especially vital for parts exposed to thermal cycling. It echoes the post’s mention of micro-machining mastery.

I’m also intrigued by the idea of integrating sensors discreetly to monitor performance. For those dabbling in this, how have you balanced the addition of wiring and sensors without affecting the engine’s thermal behaviour or mechanical reliability? Are there preferred sensor brands or protective coatings that have worked well in your builds? Any practical tips for newcomers aiming to blend precision traditional metalwork with modern instrumentation would be much appreciated!

This post really highlights how crucial precision and careful material selection are in building reliable miniature steam engines. I’ve always been fascinated by how such small-scale models can operate so efficiently with the right metalwork techniques. In my experience, achieving those airtight seals often comes down to surface finishing—especially when working with brass components. I’ve started using micro-abrasive polishing pads for critical surfaces, which has helped maintain tolerances while giving a nice finish. Has anyone experimented with different surface treatments to improve longevity and performance?

Also, I find the integration of modern sensors quite exciting. I’ve tried embedding low-profile temperature sensors under the boiler cap using heat-resistant wire coatings. It’s amazing how such technologies can provide real-time performance data without affecting the engine’s aesthetic. Are there specific sensor brands or setups that others have found particularly effective for miniature models? I’d love to hear tips on balancing modern tech with traditional craftsmanship—they seem like a perfect pair to push our hobby forward.

This post beautifully captures the convergence of classic metalworking craftsmanship and cutting-edge techniques like micro-machining and sensor integration. I’ve been working on similar projects and found that the key to achieving airtight seals involves meticulous surface finishing combined with iterative testing. One trick I’ve used is to use a small amount of fine abrasive paste on critical sealing surfaces and then to give the parts a gentle polish—this really helps seal tight without sacrificing surface quality. Also, when embedding sensors, I’ve had success with heat-resistant epoxy to protect wiring and sensors, ensuring they don’t interfere with engine operation or aesthetics. Have others experimented with different materials or coatings for enhanced durability under thermal cycling? Also, do any hobbyists here incorporate CAD/CAM software in their design process before machining? Would love to hear your experiences and tips for bridging traditional metalwork with modern electronics.

Really enjoyed reading this comprehensive post! I’ve also found that micro-honing and superfinishing not only improve the sealing but greatly enhance the engine’s operational smoothness. The challenge I often face is maintaining the tight tolerances when working with delicate alloys like phosphor bronze—sometimes the slightest mishandling can impact performance. It’s exciting to see how state-of-the-art techniques like micro-machining and sensor integration are becoming more accessible for model enthusiasts. I recently embedded a tiny thermocouple to monitor internal cylinder temperature, which has been invaluable for fine-tuning operation and preventing thermal stress. How do others ensure that such added electronics don’t interfere with the engine’s aesthetic or cause thermal issues? Are there preferred placement strategies or insulating methods that work well? Would love to hear your experiences on crafting highly precise and reliable miniature models while seamlessly blending traditional skills with modern tech.