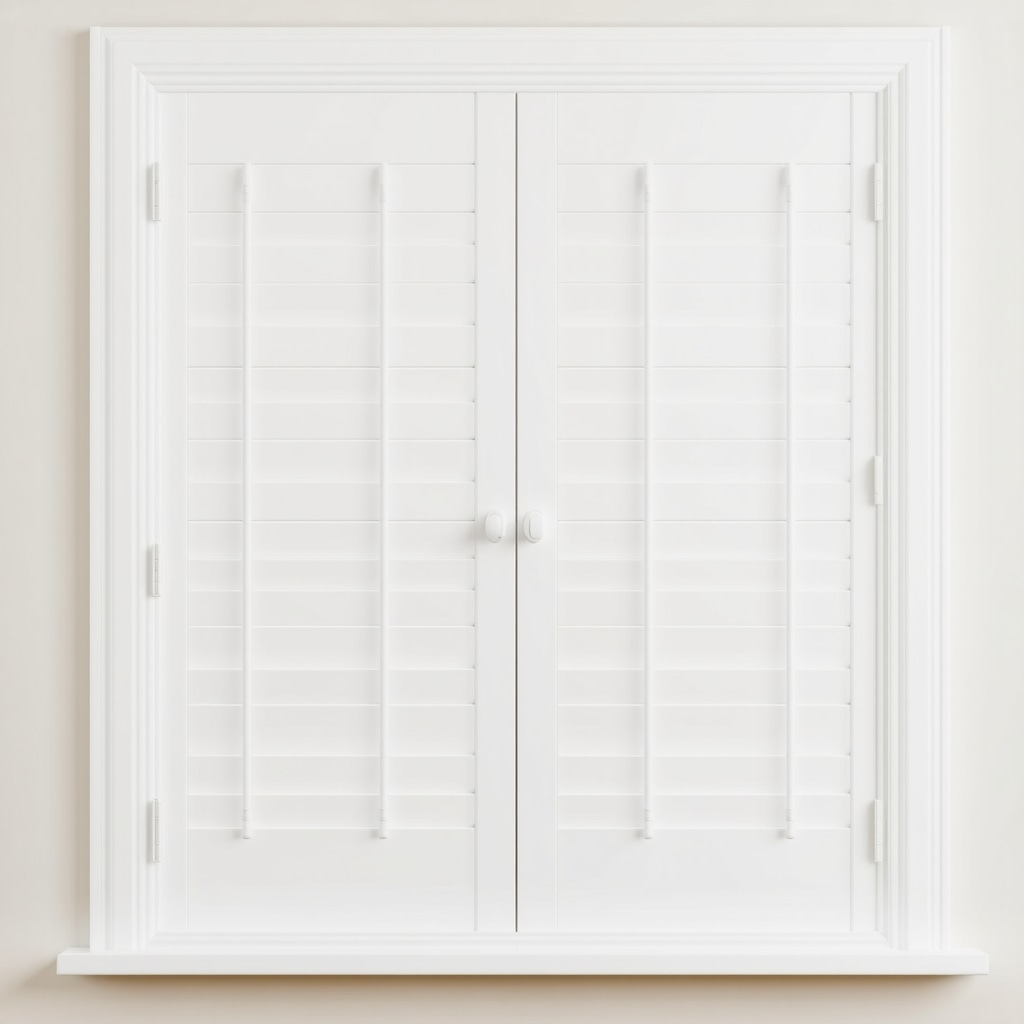

Transform Your Space: The Art and Craft of Custom Interior Window Shutters

Interior window shutters blend functionality with timeless style, offering privacy, light control, and a bespoke touch to any room. Building custom interior window shutters is a rewarding DIY project that empowers you to tailor aesthetics and fit precisely to your windows, enhancing both your home’s character and value. This guide dives deep beyond basic instructions, sharing expert insights and nuanced steps to ensure your shutter installation is seamless, durable, and visually striking.

Crafting Perfection: Precision Measuring and Material Selection

Before wielding saws and drills, meticulous measurement is paramount. Unlike prefabricated shutters, custom designs demand exact dimensions to accommodate window depth, trim, and frame irregularities. Use a steel tape measure and record width and height at three points—top, middle, and bottom—to identify any variance. Select moisture-resistant hardwoods like basswood or poplar for durability and smooth finishes that accept paint or stain beautifully. For budget-friendly alternatives, MDF can be a viable option but requires sealing to prevent warping.

Mastering the Build: Cutting, Assembly, and Panel Design

Cut your frame components with a miter saw, ensuring 45-degree joints for crisp corners. Assembly with wood glue and finish nails provides structural integrity. For panels, louvered or raised designs offer different light modulation; louvers require angled cuts and precise spacing, while raised panels necessitate routed edges for depth. Installing adjustable louvers adds versatility, allowing customized light and airflow control. Remember, pre-sanding each piece smooths surfaces and prevents paint imperfections.

How do you ensure a secure yet adjustable shutter installation?

Anchoring shutters involves installing hinge brackets within the window frame or casing. Use stainless steel or brass hinges for longevity and corrosion resistance. To enable adjustment, consider using offset hinges or inserting small shims behind hinges to fine-tune shutter positioning. Magnetic catches or small barrel bolts can secure shutters when closed without marring surfaces. This approach balances sturdiness with user-friendly operation, essential for long-term satisfaction.

Installation Insights: Aligning, Mounting, and Finishing Touches

Mount shutters by first dry-fitting to confirm alignment. Use a level and shim as needed to correct slight window frame irregularities. Pre-drill hinge holes to avoid wood splitting and secure with screws appropriate for the shutter thickness. For a polished look, fill nail holes with wood filler and sand before painting or staining. Finally, apply a durable finish, such as a polyurethane topcoat, to protect against wear and moisture, especially in kitchens or bathrooms.

Elevating Your DIY Skills: When to Consult the Experts and Further Resources

While this guide empowers confident DIY enthusiasts, complex window shapes or historic homes may require professional consultation to preserve integrity and comply with building codes. For inspiration on complementary home decor projects to enhance your interior, explore creative home decor ideas that beautifully harmonize with custom shutters.

For authoritative guidance on woodworking precision and joinery techniques, the Fine Woodworking Institute offers extensive resources that deepen craft understanding beyond basic installation — a valuable asset for serious DIYers aiming for impeccable results.

Ready to add a refined, custom touch to your windows? Share your shutter-building experiences or questions in the comments below to join a community passionate about elevating home craftsmanship.

Fine-Tuning Fit: Adjusting for Imperfections and Lasting Functionality

One lesson I quickly learned when building custom interior window shutters was that no window is perfectly square. Even after careful measurements, slight irregularities in the frame can throw off the fit. To tackle this, I started incorporating subtle shims behind hinges and along edges to ensure the shutters closed flush without binding or gaps. This small adjustment step became a game changer, avoiding frustrating rework and ensuring smooth operation over time.

Another insight was the importance of quality hardware. I opted for brass hinges and magnetic catches, which not only offered durability but added a touch of classic elegance complementing the shutters’ wood finish. According to a detailed guide from the Fine Woodworking Institute, investing in corrosion-resistant hardware pays off in both function and aesthetics, especially in humid environments like bathrooms.

Bringing Your Shutters to Life: Painting, Staining, and Protective Finishes

After assembly and fitting, the finishing phase is where your shutters truly become a part of your home’s story. I experimented with different paint and stain combinations, discovering that a satin finish strikes the perfect balance between sheen and subtlety. When staining, pre-conditioning the wood prevents blotchiness and enhances grain depth.

One technique I cherish is applying multiple thin coats of water-based polyurethane. It seals the wood beautifully without yellowing over time, preserving the original color and making cleaning easier. Plus, it’s low in VOCs, which makes the workspace more pleasant and safer.

Have you ever faced unexpected challenges while installing custom shutters that reshaped your approach?

In my early projects, I underestimated the impact of humidity fluctuations on shutter panels, leading to slight warping during seasonal changes. This prompted me to switch to more stable wood types and ensure proper acclimation before installation. Sharing these experiences with fellow DIYers has been invaluable — it’s comforting to know that challenges are part of the learning curve.

If you’re eager to expand your DIY repertoire, exploring detailed guides on step-by-step DIY projects for all skill levels can provide a structured path to mastering complex builds like shutters.

Enhancing Your Home’s Character Through Shutters and Beyond

Custom interior window shutters do more than control light—they contribute personality and warmth. Pairing them with complementary elements like tailored home decor or innovative storage hacks can elevate your entire space. For instance, integrating smart DIY storage solutions around your windows can maximize room functionality without sacrificing style.

I invite you to share your shutter-building stories or questions below. Your insights might inspire someone else navigating the same rewarding journey of home craftsmanship.

Precision Adjustments: Mastering the Art of Shutter Alignment for Irregular Windows

Custom interior window shutters challenge even seasoned woodworkers because few windows are perfectly square or uniformly deep. Beyond basic shimming, advanced techniques involve strategic material removal and hinge placement to accommodate unique window contours. For instance, selectively planing shutter edges or employing spring-loaded hinges can compensate for uneven jambs, ensuring a flush fit without sacrificing structural integrity. This nuanced approach requires a keen eye for detail and patience but results in shutters that operate smoothly and maintain aesthetic harmony.

What are the best practices for addressing asymmetrical window frames when installing custom shutters?

Dealing with asymmetrical window frames necessitates a multi-step approach. First, use a contour gauge to capture the exact shape of irregular jambs. Next, fabricate shutter frames with slightly tapered edges to match these contours. Installing adjustable hinges, such as friction or offset hinges, allows micro-positioning post-installation, accommodating any residual discrepancies. Additionally, incorporating flexible weatherstripping or felt pads at contact points can prevent rattling and wear. These methods collectively create a tailored fit that respects the window’s idiosyncrasies without compromising shutter function or appearance.

Such precision in fit and finish is crucial because even minor gaps can undermine energy efficiency and light control, two primary benefits of interior shutters.

Hardware Innovations: Selecting and Customizing Hinges, Catches, and Controls for Longevity and Style

Hardware choice transcends mere functionality; it defines the tactile experience and visual impact of your shutters. Beyond traditional brass and stainless steel, consider powder-coated aluminum or custom-machined bronze for enhanced corrosion resistance and bespoke aesthetics. For adjustable louvers, integrating magnetic or spring-loaded tilt rods offers seamless operation with minimal visible hardware, elevating the shutters’ sleekness.

Moreover, the advent of smart home integration introduces motorized shutter controls that can be discreetly incorporated into custom builds. These systems enable remote light and privacy management, marrying classic craftsmanship with modern convenience.

Investing in premium, corrosion-resistant hardware not only extends the lifespan of your shutters but also reduces maintenance needs, particularly in moisture-prone environments like kitchens and bathrooms. Referencing the Fine Woodworking Institute’s expert hardware guide provides a comprehensive overview of materials and mechanisms suited for various climates and design goals.

Advanced Finishing Techniques: Enhancing Durability and Visual Appeal with Layered Coatings and Specialty Treatments

While a satin water-based polyurethane is a reliable choice, exploring layered finishing techniques can dramatically boost your shutters’ performance and artistry. For example, applying a stain-sealant hybrid before the topcoat can deepen wood grain contrast while providing an initial moisture barrier. Following this, multiple ultra-thin coats of catalyzed lacquer or conversion varnish can yield a hard, chemical-resistant finish prized in high-traffic areas.

For those seeking decorative flourishes, techniques like glazing or antiquing introduce subtle patinas that enhance depth and character, especially on raised panels or intricate louver profiles. It’s essential to balance these aesthetics with protective qualities to prevent premature wear.

Additionally, UV-resistant finishes guard against color fading in sun-exposed rooms, preserving your shutters’ vibrancy year-round. Employing a spray application with HVLP (High Volume Low Pressure) equipment ensures even coverage and a professional-grade finish that hand brushing often cannot replicate.

Integrating Sustainability: Choosing Eco-Friendly Materials and Finishes Without Compromising Quality

As environmental consciousness grows, many woodworkers and homeowners seek sustainable alternatives for custom shutters. Certified reclaimed hardwoods or rapidly renewable species like bamboo offer eco-friendly options without sacrificing durability or beauty. Pairing these with low-VOC, water-based finishes aligns with green building principles, reducing indoor pollutants and environmental impact.

Moreover, sourcing hardware from manufacturers committed to ethical practices and longevity minimizes waste and supports responsible consumption. This holistic approach to shutter construction not only elevates your home’s aesthetic and functional qualities but also contributes positively to the planet.

For those interested in detailed environmental assessments of woodworking materials and finishes, resources such as the Forest Stewardship Council (FSC) provide trusted certifications and guidelines.

Ready to elevate your custom shutter project with these advanced strategies? Dive deeper into specialty woodworking forums or consult with seasoned professionals to tailor solutions that perfectly fit your unique space and vision.

Precision Engineering: Tailoring Shutter Frames to Complex Window Profiles

Mastering the fit of custom interior shutters demands more than standard measurements; it requires adapting to the idiosyncrasies of each window’s architecture. Employing contour gauges to replicate asymmetric jambs allows for meticulous shaping of shutter edges, ensuring a seamless interface. This precision is further enhanced by integrating tapered frame components and adjustable hardware, facilitating micro-alignments post-installation. Such bespoke adjustments are critical for maintaining shutter performance, minimizing drafts, and preserving aesthetic integrity over time.

What advanced methods optimize shutter fit on irregular window frames?

Advanced approaches include capturing exact jamb contours with contour gauges, fabricating tapered shutter edges, and utilizing friction or offset hinges for fine-tuned positioning. Complementing these with flexible weatherstripping or felt pads reduces noise and wear, delivering a fit that is both functional and visually cohesive. These techniques collectively mitigate common issues arising from asymmetrical frames, ensuring your custom shutters operate flawlessly.

Innovating Hardware: Beyond Tradition to Smart and Durable Shutter Solutions

Hardware selection transcends basic utility, embodying durability and tactile refinement. Materials such as powder-coated aluminum and bespoke bronze elevate corrosion resistance and style. Incorporating magnetic or spring-loaded tilt rods streamlines louver adjustment, eliminating cumbersome mechanisms. The integration of motorized controls introduces a cutting-edge dimension, enabling remote operation and synchronization with smart home systems, thereby marrying artisanal craftsmanship with contemporary convenience for discerning homeowners.

Layered Finishing Mastery: Combining Aesthetics with Longevity Through Specialty Coatings

Elevate your shutters’ finish by embracing multi-layered application strategies. Starting with stain-sealant hybrids enhances grain richness while affording moisture protection. Following this, ultra-thin coats of catalyzed lacquer or conversion varnish yield a resilient, chemical-resistant surface optimal for high-traffic zones. Decorative techniques like glazing or antiquing add nuanced patinas, enriching visual depth without compromising protection. UV-resistant topcoats further preserve color vibrancy in sunlit interiors, ensuring enduring beauty.

Sustainable Craftsmanship: Integrating Eco-Conscious Materials and Ethical Sourcing

Environmental stewardship in shutter production is achievable without sacrificing quality. Utilizing FSC-certified reclaimed hardwoods and rapidly renewable materials such as bamboo supports sustainability while offering exceptional durability and aesthetics. Coupling these with low-VOC, water-based finishes reduces indoor air pollutants and ecological footprints. Additionally, selecting hardware from manufacturers adhering to ethical labor and environmental standards reinforces responsible consumption, aligning your project with modern green building practices.

For comprehensive insights into eco-friendly woodworking, the Forest Stewardship Council (FSC) provides authoritative certifications and guidelines that ensure material traceability and sustainability.

Engage with Expert Strategies to Refine Your Custom Shutter Craftsmanship

These advanced techniques and innovations offer a blueprint for transforming your custom interior window shutters into enduring masterpieces of function and style. Dive into specialized woodworking forums, consult industry experts, and experiment with these refined methods to elevate your project beyond conventional standards. Share your experiences or pose questions to join a community dedicated to pushing the boundaries of home craftsmanship excellence.

Frequently Asked Questions (FAQ)

What are the key benefits of custom interior window shutters compared to ready-made options?

Custom interior window shutters offer precise fit tailored to your unique window dimensions and architectural nuances, ensuring optimal light control, privacy, and energy efficiency. Unlike prefabricated shutters, they accommodate irregular frames and allow personalized design choices in materials, finishes, and hardware, resulting in a seamless integration with your home’s style and superior durability.

How can I accurately measure irregular or asymmetrical windows for shutter installation?

Use a steel tape measure to record widths and heights at multiple points—top, middle, and bottom—to detect variances. Employ contour gauges to capture irregular jamb profiles, enabling fabrication of tapered or shaped shutter edges. Document all measurements meticulously before cutting, and consider creating a cardboard template to verify fit prior to final production.

Which hardwoods are best suited for durable and stable custom shutters, especially in humid environments?

Moisture-resistant hardwoods such as basswood, poplar, and reclaimed oak are excellent choices due to their dimensional stability and fine grain, which enhances finish quality. Avoid woods prone to warping, and if using MDF, seal thoroughly to prevent moisture absorption. Selecting corrosion-resistant hardware further protects shutter longevity in moisture-prone areas like bathrooms or kitchens.

What hardware options optimize shutter functionality while maintaining aesthetic appeal?

Brass and stainless steel hinges offer durability and corrosion resistance, with offset or friction hinges enabling precise alignment adjustments. Magnetic catches or barrel bolts secure shutters discreetly without damaging surfaces. For louvers, magnetic or spring-loaded tilt rods provide smooth operation with minimal visible hardware. Advanced options include motorized controls for remote operation, integrating traditional craftsmanship with smart home convenience.

How do layered finishing techniques improve shutter durability and appearance?

Applying a stain-sealant hybrid deepens wood grain and provides initial moisture protection, followed by multiple ultra-thin coats of catalyzed lacquer or conversion varnish for chemical resistance and hardness. Decorative glazing or antiquing adds patina and depth without sacrificing protection. UV-resistant topcoats preserve color vibrancy in sun-exposed rooms, ensuring lasting beauty and performance.

What strategies help achieve a perfect shutter fit on windows with uneven frames?

Incorporate shims behind hinges and along shutter edges to compensate for frame irregularities. Fabricate tapered shutter components based on contour gauge readings to match asymmetric jambs. Use adjustable hardware such as offset or friction hinges for fine positioning. Adding flexible weatherstripping or felt pads at contact points reduces rattling and wear, ensuring smooth operation and energy efficiency.

Are eco-friendly materials and finishes viable for high-quality custom shutters?

Yes, certified reclaimed hardwoods and rapidly renewable species like bamboo provide sustainable, durable options. Low-VOC, water-based finishes minimize indoor pollutants and environmental impact without compromising durability. Selecting hardware from ethical manufacturers supports responsible consumption. These choices align with green building practices while delivering aesthetic and functional excellence.

When should I consult professionals during a custom shutter project?

Consult experts for complex window shapes, historic homes, or when local building codes mandate specific standards. Professionals can ensure structural integrity, compliance, and optimal finishing techniques. Additionally, they can assist in integrating smart hardware or advanced finishes, providing expertise that elevates your project beyond basic DIY capabilities.

Can custom interior shutters be integrated with smart home technology?

Absolutely. Motorized shutter hardware can be discreetly installed within custom builds, allowing remote control via apps or voice commands. This fusion of traditional craftsmanship and modern technology enhances convenience, energy management, and security. Planning for wiring and hardware placement during design ensures seamless integration without compromising aesthetics.

How do I maintain and care for custom interior shutters to ensure longevity?

Regular dusting and gentle cleaning with non-abrasive products preserve finishes. Inspect hardware periodically for loosening or corrosion, lubricating moving parts as needed. Avoid excessive moisture exposure, and promptly repair any damage to prevent deterioration. Proper maintenance extends the life and appearance of your shutters for decades.

Trusted External Sources

- Fine Woodworking Institute: Offers comprehensive tutorials on woodworking techniques, hardware selection, and finishing methods essential for crafting durable and elegant interior shutters.

- Forest Stewardship Council (FSC): Provides certification standards and guidelines for sustainably sourced wood, guiding eco-conscious material selection for custom shutter projects.

- Journal of Architectural Conservation: Features research on historic window treatments and preservation methods, invaluable for projects involving heritage homes or complex window profiles.

- American Society of Interior Designers (ASID): Delivers insights into integrating custom shutters within contemporary interior design trends and functional space planning.

- National Wood Flooring Association (NWFA): Although focused on flooring, their expertise on wood finishing and moisture management translates effectively to shutter finishing and maintenance best practices.

Conclusion

Crafting custom interior window shutters is a sophisticated endeavor that harmonizes precision engineering, quality materials, and artistic finishing to transform your living space. This article has explored meticulous measurement strategies, advanced hardware innovations, layered finishing techniques, and sustainable practices that collectively elevate shutter craftsmanship to expert levels. Addressing irregular window frames with tailored adjustments and embracing eco-friendly materials ensures your shutters not only fit perfectly but also align with modern environmental values. By integrating smart technology and consulting professionals when needed, your custom shutters become a seamless fusion of tradition and innovation, enhancing both function and style. Embark on your shutter project equipped with these expert insights, and share your journey to inspire a community passionate about refined home craftsmanship. Dive deeper into related expert content, comment with your experiences, and transform your windows into timeless statements of personalized design.

I’ve recently started a project to build custom interior window shutters for my older home, and this guide really resonates with what I’ve been learning so far — especially the emphasis on precise measurements for uneven window frames. I found that using a contour gauge was invaluable for capturing odd jamb shapes, which helped immensely when I tapered the shutter edges to fit perfectly. Also, incorporating shims behind hinges saved me a lot of adjustment headaches, ensuring the shutters close smoothly without gaps or binding. One challenge I encountered was deciding on the type of wood; I settled on poplar due to its moisture resistance and smooth finish, but I’m curious how others have found different types hold up over time, especially in humid rooms like bathrooms. Has anyone experimented with eco-friendly materials like bamboo for shutters and seen good durability? Additionally, I’m considering integrating magnetic catches to avoid visible latches and maintain a sleek look — any tips from readers on the best hardware choices that balance function and style? I’d love to hear how others balance craftsmanship with modern convenience in their shutter installations!

Jessica, I really appreciate your points on measurement precision and hardware choices — especially in older homes with tricky window profiles. From my experience, bamboo can be a fantastic eco-friendly option for shutters, particularly when treated properly for moisture resistance. Bamboo’s natural density gives it strength comparable to traditional hardwoods, making it a durable choice even for bathrooms. Just ensure it’s sealed with a quality low-VOC finish to protect against humidity fluctuations.

Regarding hardware, magnetic catches do indeed help maintain a clean aesthetic, but I found that pairing them with offset brass hinges offers the best compromise between adjustability and durability. The offset hinges allow for fine-tuning alignment after installation, which is invaluable with uneven frames. For a modern touch, some manufacturers now offer powder-coated aluminium hardware that combines corrosion resistance with sleek finishes, which might be a neat alternative to classical brass.

One challenge I faced was anticipating seasonal wood movement. Pre-acclimating bamboo or hardwood panels to the room’s climate for a week or more before installation helped prevent warping. Has anyone experimented with acclimation periods or alternative finishes to further mitigate this? Would love to hear how others manage those subtle but impactful factors in shutter longevity!

I’ve been really impressed by the emphasis on precision measuring and adaptable hardware in this guide. In my recent shutter project, I found that accounting for window depth variability was crucial, especially with older windows that aren’t perfectly square. While shims behind hinges do help, I also experimented with slightly planing the shutter edges where the jamb was particularly uneven, which provided a more seamless fit without causing gaps or pressure points.

On the topic of finishes, I appreciated the suggestion to apply multiple thin coats of water-based polyurethane. It protected my shutters from moisture, particularly in our humid coastal climate, and avoided the yellowing issue I’ve seen with oil-based finishes. However, I also tried a layering approach incorporating a stain-sealant hybrid before the topcoat, which really enhanced the wood’s grain and added another moisture barrier. This combo has stood up well over several months of humidity and occasional cleaning.

For those juggling style and functionality, what strategies have you found effective for integrating durable yet visually minimal hardware? I’ve toyed with magnetic catches but wondered if alternatives exist that maintain sleekness without complicating operation or maintenance? Sharing these hardware nuances really helps the DIY community elevate their projects!

This is a fantastic, detailed walkthrough of building and installing custom interior shutters. I particularly appreciated the emphasis on measuring accuracy and the use of contour gauges to accommodate uneven frames—something that I found to be crucial in my own projects. The tips on using shims and tapered edges are game changers for ensuring a snug fit, especially in older or irregular windows.

I’ve been exploring eco-friendly materials for my projects and have had great success with bamboo, particularly because it’s fast-growing and sustainable. Proper sealing with low-VOC finishes has helped me maintain durability in humid environments like bathrooms and kitchens. Has anyone experimented with bamboo in humid conditions long-term? Would love to hear your experiences!

On hardware, I think magnetic catches coupled with adjustable hinges can strike a good balance between aesthetics and functionality. Has anyone used smart, motorised systems to control shutters? It seems like a handy upgrade but wonder if it complicates the aesthetic and installation process.

This article provides some really practical insights into the finer details of shutter installation, especially the emphasis on measuring accuracy and hardware flexibility. I found that pre-assembling smaller sections before fitting helps me catch any discrepancies early on, saving a lot of rework later. The mention of using shims behind hinges to accommodate uneven frames is a simple yet effective tip that I’ve relied on in my projects.

One thing I’ve learned over time is the importance of matching hardware to the room’s environment; for instance, in high humidity areas, choosing stainless steel or corrosion-resistant finishes can significantly reduce maintenance. I’ve also experimented with different eco-friendly finishes, such as low-VOC oils and water-based stains, which work well without sacrificing durability. Has anyone tried combining these with traditional sealing methods to extend longevity?

I’m curious what others do to balance aesthetic appeal with hardware longevity, especially with modern features like motorised controls that can add a sleek look without overpowering the traditional charm. Would be great to hear more tips on integrating smart tech subtly into these classic designs!

Building my own custom interior shutters was definitely a rewarding experience, especially when I took the time to consider irregular window frames. I found that using an contour gauge really helped me capture those tricky shapes accurately, which saved me a lot of adjustments later. The tip about adjustable hardware, like friction hinges, proved invaluable because it allowed me to fine-tune the fit even after mounting. Personally, I’ve started exploring eco-friendly materials—bamboo was a great choice for durability and sustainability, especially once properly sealed against humidity.

I’m curious, for those integrating motorized controls, how do you handle the wiring without compromising design? Do you find that the added technology increases maintenance, or does it generally work smoothly? I think combining classic craftsmanship with modern tech can really elevate home interiors, but it’s also important to keep it simple enough for everyday use. Would love to hear your experiences on balancing aesthetics with functionality and durability in smart shutter systems.

Building custom shutters really opened my eyes to how important precise measurements are, especially for older, irregular windows. I used a contour gauge myself, which was a game-changer for capturing those tricky shapes accurately. I also found that employing adjustable hinges, like friction hinges, allowed me to make micro-adjustments after fitting the shutters, saving me from redoing the entire project. Personally, I chose bamboo for its sustainability and durability, especially when sealed with a low-VOC finish—perfect for humid areas.

For those considering motorized controls, I think cleverly hiding the wiring within the wall or ceiling cavity can keep the aesthetic clean. Has anyone managed to do this without impacting the visual appeal? I’m interested to hear about your experiences and any tips for blending modern tech into traditional craftsmanship seamlessly.

Building my own shutters was quite the journey, and I totally agree with the importance of precise measurements—especially in older homes with irregular windows. Using a contour gauge really made a difference for me, capturing those tricky shapes accurately. I also found that incorporating adjustable hardware like friction hinges allowed me to fine-tune the fit after installation, which saved me from a lot of rework. In terms of materials, I’ve just started experimenting with bamboo, and it’s surprisingly durable if sealed properly.

One thing I’m curious about is how others handle wiring for motorized controls without sacrificing the clean look. I love the idea of integrating smart tech, but managing the wiring discreetly seems challenging. Has anyone here successfully installed motorized shutters that blend seamlessly with classic design? Also, what eco-friendly finishes have you found work well long-term, especially in humid environments? Looking forward to hearing tips and experiences from this community!

I’ve been working on custom interior shutters myself, and I completely resonate with the point about embracing imperfections like uneven window frames. What really helped me was the suggestion in this guide about using adjustable hardware, especially friction hinges, which gave me the flexibility to micro-adjust shutter positioning after mounting. This fine-tuning made a massive difference in both fit and function.

Regarding the choice of wood, I opted for reclaimed oak, inspired by the sustainability aspect mentioned here. Over the last year, they’ve held up impressively well in my humid kitchen area without any warping, likely due to the careful sealing and multiple thin coats of water-based polyurethane the guide recommended. The environmental benefits paired with durability make it a winning combo.

I’m curious to hear if others have tried integrating smart home features like motorized controls with their shutters? I’m considering adding remote operation for convenience but wondering about the practicality and installation challenges involved. Has anyone successfully navigated this blend of classic craftsmanship and modern tech? It would be great to learn from your experiences or insights!

I’ve been following this guide closely as I embarked on installing custom interior shutters in my home, and one aspect that stood out to me was the combination of precision measuring with adaptable hardware choices to handle irregular window frames. In my experience, using a contour gauge early on saved me a lot of headache, especially since a couple of my windows have deeper jambs on one side due to some uneven plastering. Rather than forcing the shutters to fit blindly, I shaped the edges slightly tapered and used offset hinges with shims behind them to tweak the fit perfectly.

I also wanted to add my two cents on finishes. After some trial and error, I found that applying a stain-sealant hybrid before any polyurethane really enhanced the wood grain and acted as an extra moisture barrier, which is crucial for the humid climate here in Brisbane. I’m curious if anyone else has tried combining these finishing layers and how that affected long-term durability or if they used alternative eco-friendly sealants that worked well?

Another point: integrating smart motorized controls sounds fascinating but seems quite technical. I’d love to hear about the practical challenges or benefits others have encountered blending traditional shutter craftsmanship with modern smart home tech. Has anyone managed a smooth installation without compromise on aesthetics?