Steam Dreams and Metal Schemes: The Allure of Miniature Engines

Ever been captivated by the mesmerizing hiss and puff of a steam engine? That archaic symphony of valves and pistons isn’t just for museum buffs or railway enthusiasts. Building a functional miniature steam engine from metal is a captivating journey into mechanical artistry and engineering finesse. It’s where DIY meets industrial revolution nostalgia, and the result is a tiny marvel that hisses with life.

Why Build Your Own Miniature Steam Engine? Because Adulting Needs Steam Power

Crafting a miniature steam engine is not just about assembling parts; it’s about reviving the magic of steam power on a scale you can hold in your hand. It challenges your metalworking skills, your patience, and your creativity. Plus, it’s a fantastic conversation starter—who wouldn’t want a desktop engine chugging away as you work?

Is It Really Worth the Sweat and Sparks?

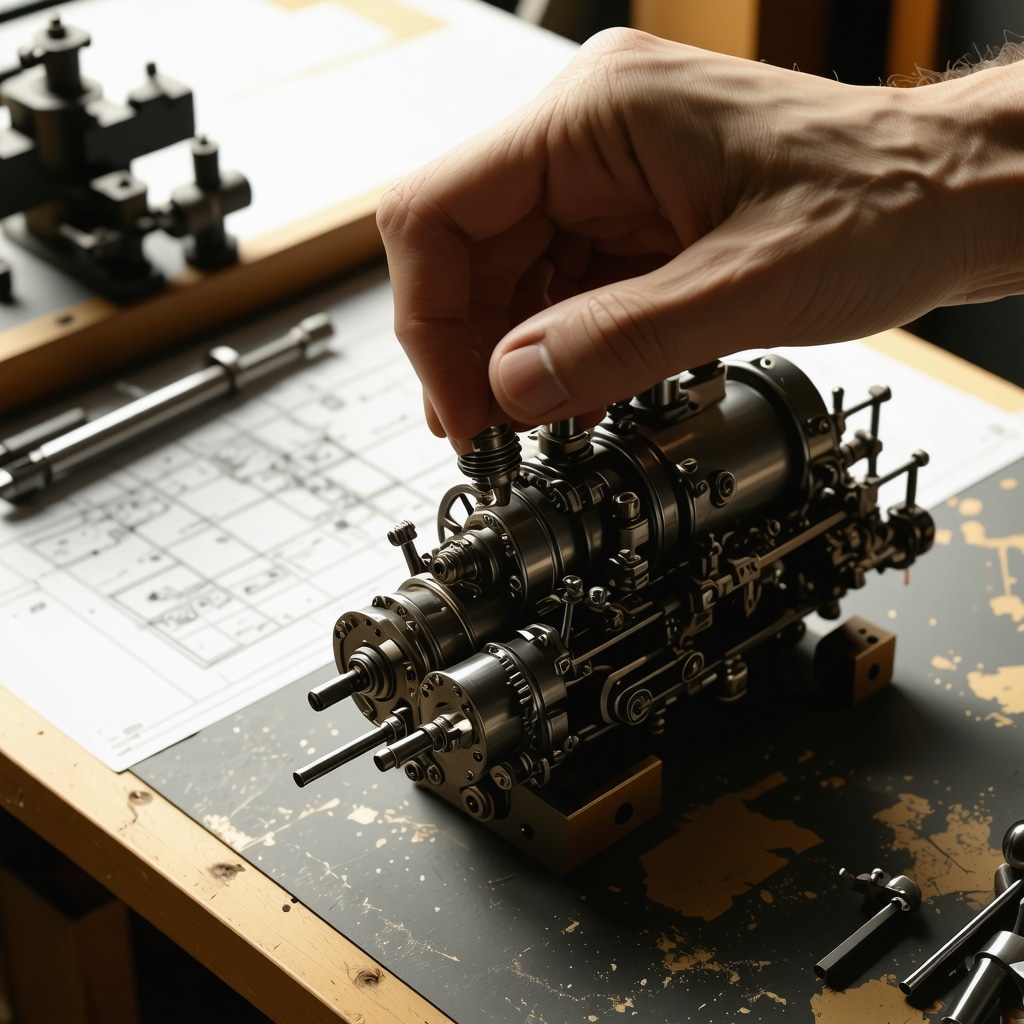

Ask any seasoned builder, and they’ll tell you it’s a labor of love. From cutting and shaping metal components to mastering the boiler’s pressure dynamics, every step demands precision and care. The payoff? A working steam engine that’s both a mechanical puzzle and a testament to your craftsmanship. It’s educational, rewarding, and downright fun.

Getting Started: Metal Matters and Tools of the Trade

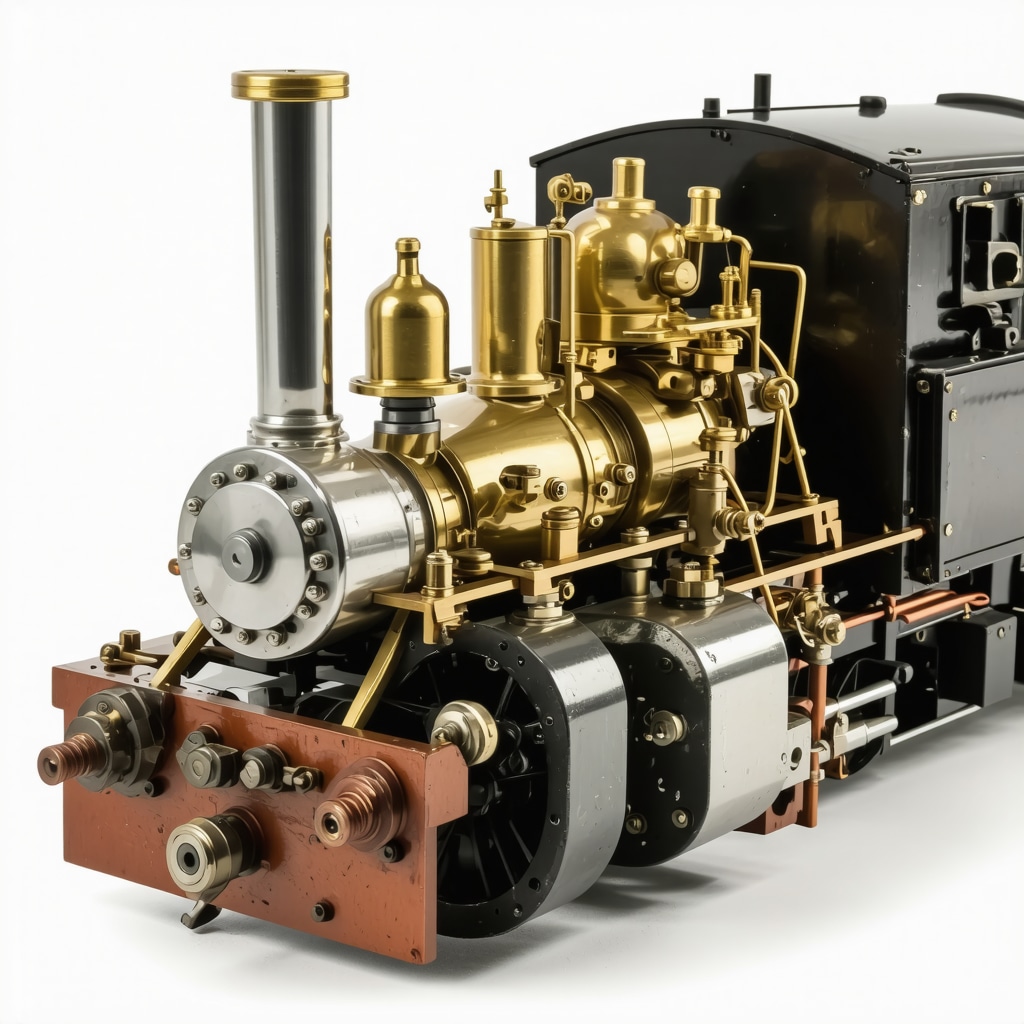

First things first, choosing the right metal is crucial. Brass and steel are popular choices—brass for its machinability and corrosion resistance, steel for robustness. You’ll want a lathe for shaping parts, a small drill press for precision holes, and a soldering iron or welding setup for assembly. Don’t forget safety gear; steam engines play with pressure and heat, and a cautious builder is a happy builder.

From Blueprint to Boiler: The Anatomy of Your Miniature Marvel

Understanding the core components—the boiler, piston, cylinder, and flywheel—is key. Each piece must be crafted to exacting standards to ensure smooth operation. The boiler, the heart of your engine, needs to withstand steam pressure safely. Tips and tricks for shaping and sealing the boiler can be found in detailed guides like this step-by-step tutorial, which walks you through the intricacies of metal steam engine construction.

Expert Tip: Why Precision Can’t Be Overstated

Even the slightest misalignment can cause your engine to stall or leak. Precision machining and patience are your best allies. Use a micrometer for measuring, and test components individually before assembly. Remember, the charm of steam engines is in their smooth, rhythmic motion—a mechanical ballet that rewards your meticulous efforts.

Want to See Steam in Action? Share Your Journey!

If you’re fired up to embark on this metalworking adventure, why not share your progress and tips in the comments? Whether you’re a beginner or a seasoned metal artist, exchanging stories and challenges enriches the experience. And if you crave more creative projects to brighten up your workspace, be sure to explore easy crafts to brighten up your home decor that complement your miniature steam engine’s vintage charm.

For those fascinated by the science behind steam engines, the International Journal of Mechanical Sciences offers detailed research on steam engine thermodynamics, a treasure trove for the curious mind.

Fine-Tuning Your Miniature Steam Engine: The Art of Adjustment and Maintenance

Once your miniature steam engine is assembled and steaming, the journey is far from over. Fine-tuning your engine ensures it runs smoothly and efficiently, extending its lifespan and enhancing your enjoyment. Attention to detail during adjustments—such as calibrating the boiler pressure, lubricating moving parts, and aligning the crankshaft—prevents common issues like leaks or erratic operation. Regular maintenance, including cleaning scale buildup and inspecting seals, is essential for reliable performance.

For enthusiasts seeking to elevate their craftsmanship, consider exploring smart DIY ideas for everyday problems to incorporate innovative solutions that can automate or simplify maintenance tasks.

How Does Understanding Steam Thermodynamics Enhance Your Miniature Engine’s Performance?

Delving into the principles of steam thermodynamics can transform your approach from mere assembly to engineering mastery. Grasping concepts like enthalpy, pressure-volume relationships, and heat transfer helps you optimize boiler design and operating parameters. This knowledge minimizes energy waste and maximizes power output, making your miniature engine both a functional machine and an educational model of industrial mechanics.

For those intrigued by the science behind steam engines, the International Journal of Mechanical Sciences provides peer-reviewed research that deepens understanding of steam engine thermodynamics and efficiency.

Innovative Materials and Techniques: Pushing the Boundaries of Miniature Steam Engines

While traditional metals like brass and steel remain favorites, experimenting with advanced materials such as stainless steel or even titanium alloys can offer enhanced durability and corrosion resistance. Incorporating modern sealing techniques, like high-temperature silicone gaskets or custom-machined PTFE seals, can drastically reduce steam leaks, improving safety and performance.

Additionally, integrating precision 3D-printed components for non-structural parts enables rapid prototyping and customization. This intersection of classic metalworking and contemporary technology exemplifies how miniature steam engine building is evolving, offering endless opportunities for innovation.

Share Your Steam Engine Successes and Explore More Creative Projects

Have you tackled the challenge of building a miniature steam engine or innovated on traditional designs? Share your experiences, tips, or questions in the comments below to inspire and assist fellow enthusiasts. Your insights contribute to a vibrant community eager to learn and create.

Don’t stop here—explore more unique DIY crafts to enhance your home decor or discover engaging DIY projects for all skill levels that complement your steam engine journey and spark further creativity.

Mastering Miniature Steam Engines: Advanced Material Science Meets Precision Engineering

As builders progress beyond the basics of miniature steam engine construction, the choice of materials and the precision of fabrication take on critical importance. Moving past traditional brass and steel, many experts now experiment with stainless steel and titanium alloys. These metals offer superior strength-to-weight ratios and exceptional corrosion resistance, making them ideal for long-term durability and performance under high-temperature steam conditions. However, working with such advanced materials requires specialized tooling and knowledge — for instance, titanium’s toughness demands high-quality carbide cutting tools and controlled machining environments to avoid work hardening or cracking.

In addition, adopting modern sealing technologies, such as high-temperature silicone gaskets and custom PTFE (polytetrafluoroethylene) seals, has revolutionized steam containment. These seals provide a tighter barrier against steam leaks, which historically have been a persistent challenge in miniature boiler design. The integration of these materials not only enhances safety but also markedly improves engine efficiency by maintaining optimal pressure levels consistently.

Innovative Manufacturing: Combining Traditional Craftsmanship with 3D Printing Precision

The fusion of classic metalworking skills with cutting-edge additive manufacturing opens new frontiers for miniaturized steam engines. Precision 3D printing enables the rapid prototyping of complex, non-structural components such as valve bodies, throttle controls, or aesthetic elements. This hybrid approach allows builders to customize features tailored to specific operational needs or stylistic preferences without the time and expense of full metal machining.

Moreover, 3D-printed polymer parts can be engineered with intricate internal channels that facilitate steam flow or lubrication, features difficult or impossible to achieve with conventional machining. By integrating these components seamlessly, the builder achieves an engine that is both mechanically robust and functionally optimized.

What Are the Thermodynamic Considerations for Optimizing Miniature Steam Engine Efficiency?

Understanding the thermodynamics behind steam engines is essential for refining performance. The steam cycle involves complex heat and mass transfer phenomena; thus, parameters such as boiler pressure, steam temperature, and expansion ratios must be carefully balanced. For example, increasing boiler pressure raises the energy content of steam, improving power output, but also demands stronger materials and more precise fabrication to withstand the stress.

Additionally, minimizing heat loss from the boiler and steam lines via insulation preserves thermal energy, enhancing overall efficiency. The International Journal of Mechanical Sciences presents in-depth analyses on steam engine thermodynamics, highlighting models that predict performance outcomes based on varying operational parameters (source).

Integrating Smart Monitoring: The Future of DIY Miniature Steam Engines

Incorporating smart sensors and microcontrollers into your steam engine project can elevate it from a static model to an interactive engineering system. Pressure sensors, temperature probes, and flow meters connected to simple Arduino or Raspberry Pi units provide real-time data, enabling precise control over combustion, steam generation, and mechanical motion. This digital feedback loop facilitates proactive maintenance alerts, optimizing engine longevity and safety.

Such integration also broadens educational value, allowing hobbyists to experiment with control algorithms or data visualization, marrying mechanical tradition with modern IoT (Internet of Things) technologies. This approach is gaining traction among advanced model engineers who seek to push the boundaries of miniature steam power.

Join the Expert Community and Elevate Your Steam Engine Craft

Ready to deepen your expertise and innovate further? Engage with specialized forums, attend workshops, or subscribe to journals focused on mechanical engineering and model steam technology. Sharing your experiments and challenges not only contributes to collective knowledge but also accelerates your own learning curve.

Explore more advanced DIY projects and stay updated with the latest materials and techniques to enhance your miniature steam engine’s performance and aesthetic appeal. Your journey from passionate builder to seasoned engineer begins with curiosity and continuous learning—ignite that spark today!

Elevate Your Craft: Advanced Metal Choices and Their Impact on Engine Longevity

For the seasoned miniature steam engine builder, material selection transcends the traditional brass and steel. Stainless steel and titanium alloys are becoming the metals of choice among experts aiming for superior strength-to-weight ratios and exceptional corrosion resistance. Titanium, in particular, offers remarkable thermal stability and resilience under high-pressure steam environments, but machining it requires advanced knowledge and specialized cutting tools to prevent work hardening and microfractures. The investment in mastering these materials pays off in engines that not only perform better but also withstand the test of time and repeated thermal cycling.

Precision Engineering Meets Smart Tech: How IoT is Transforming Model Steam Engines

Integrating smart sensors and microcontrollers into miniature steam engines ushers in a new era of interactive and educational models. Pressure sensors, temperature probes, and flow meters connected to Arduino or Raspberry Pi platforms enable real-time monitoring and control of critical parameters. This feedback loop allows builders to fine-tune combustion rates, optimize steam generation, and detect leaks or maintenance needs before they escalate. Beyond functionality, this marriage of classic steam engineering and modern IoT technology enhances the learning curve, making every steam puff an opportunity for data-driven experimentation and innovation.

How Can Thermodynamic Modeling Refine Miniature Steam Engine Performance?

Thermodynamics lies at the heart of steam engine efficiency, guiding builders in balancing boiler pressure, steam temperature, and expansion ratios. Employing computational models to simulate heat transfer and fluid dynamics can reveal inefficiencies invisible to the naked eye, such as localized heat loss or suboptimal valve timing. By iterating designs based on these insights, model engineers can maximize power output while minimizing fuel consumption and wear. For those eager to deepen their theoretical foundation, the International Journal of Mechanical Sciences offers rigorous peer-reviewed studies that illuminate the complex interplay of thermodynamic variables in steam engine cycles.

Embracing these advanced approaches not only hones your engineering acumen but also fosters innovation in a field steeped in tradition. If you’re passionate about pushing the boundaries of your miniature steam engine projects or integrating smart DIY solutions, don’t hesitate to share your experiences and insights in the comments below. And while you’re at it, explore more smart DIY innovations to complement your mechanical artistry, or dive into creative crafts that brighten your workspace and spark fresh inspiration.

Expert Insights & Advanced Considerations

Precision Machining Is the Linchpin of Reliable Steam Engine Performance

In miniature steam engine construction, the margin for error is razor-thin. Even minor deviations in component dimensions or alignment can cause leaks, inefficiencies, or mechanical failures. Employing precision machining tools such as micrometers and digital calipers, along with methodical test fitting, ensures the seamless operation that defines a truly functional and durable model.

Advanced Materials Elevate Durability but Demand Specialized Skills

Transitioning from traditional brass and steel to stainless steel or titanium alloys dramatically improves corrosion resistance and strength-to-weight ratios. However, these materials require high-end tooling and experience to machine effectively. For example, titanium’s propensity for work hardening necessitates controlled cutting speeds and premium carbide tools, underscoring the importance of material-specific knowledge in advancing your craftsmanship.

Integrating IoT Technologies Enhances Safety and Educational Value

Embedding sensors and microcontrollers within your miniature steam engine transforms it from a static exhibit to an interactive system. Real-time monitoring of pressure, temperature, and flow enables fine-tuning and proactive maintenance, while also providing a platform for experimenting with control algorithms. This fusion of classic mechanics and modern technology enriches both hobbyist engagement and educational potential.

Thermodynamic Modeling Offers a Pathway to Optimal Efficiency

Delving into steam thermodynamics empowers builders to refine boiler pressure settings, steam expansion ratios, and insulation strategies. Computational models can reveal subtle inefficiencies, guiding iterative design improvements. Understanding these principles not only maximizes power output but also elevates your miniature steam engine into a sophisticated model of industrial engineering.

Hybrid Manufacturing Techniques Foster Innovation and Customization

Combining traditional metalworking with precision 3D printing unlocks new design possibilities. Rapid prototyping of non-structural components such as valve bodies or aesthetic elements enables customization and functional enhancements without the cost and time of full metal fabrication. This synergy exemplifies how the craft is evolving, inviting builders to push creative and technical boundaries.

Curated Expert Resources

International Journal of Mechanical Sciences: A peer-reviewed source providing in-depth research on steam engine thermodynamics and efficiency modeling, essential for advancing understanding beyond the basics.

https://en.diykutak.com/how-to-build-a-functional-miniature-steam-engine-from-metal-parts: An invaluable step-by-step tutorial detailing metalworking techniques and assembly processes tailored for miniature steam engines.

https://en.diykutak.com/smart-diy-innovative-solutions-for-modern-living: Explores integration of smart technologies such as sensors and microcontrollers in DIY projects, perfect for those looking to modernize their steam engine builds.

https://en.diykutak.com/creative-solutions-for-home-decor-unique-diy-crafts-to-try: Offers creative crafting ideas that complement the aesthetic and vintage appeal of miniature steam engines, enriching your workspace ambiance.

Specialized Forums and Workshops: Engage with communities and attend events focused on model engineering and steam technology to exchange knowledge, troubleshoot challenges, and stay abreast of emerging techniques.

Final Expert Perspective

The journey of crafting a miniature steam engine from metal is a compelling blend of art, science, and engineering mastery. Precision machining, advanced materials, and smart technologies collectively redefine what is achievable on a miniature scale. Integrating thermodynamic understanding and innovative manufacturing methods not only enhances performance but also deepens the educational and experiential value of your project. Embrace this synthesis of tradition and innovation — and consider sharing your expertise or exploring further advanced DIY projects like those found in creative home decor crafts or engaging crafts for all skill levels. Your miniature steam engine can be both a personal triumph and a contribution to a vibrant community of makers eager to learn and innovate.

The post brilliantly captures the allure of building miniature steam engines—it truly is a blend of art, science, and skilled craftsmanship. I recently embarked on my first project making a small steam engine from brass, and the precision required really opened my eyes to the intricacies involved. The tiniest misalignment with the piston and cylinder caused frustrating leaks and performance issues, so I wholeheartedly agree on the importance of meticulous measurement and fitting. What struck me most was how much patience this craft demands; it’s not just about metalworking skills but learning to troubleshoot and fine-tune as you go, which deepens your appreciation of the steam engine’s mechanical ballet. I’m curious how others manage the balance between traditional manual machining and the integration of newer tech like 3D-printed parts or IoT sensors—as fascinating as the smart monitoring seems, I wonder if it takes away some of the hands-on intimacy with the engine or enhances the learning experience? For anyone juggling both approaches, what’s your take on maintaining that connection to classic craftsmanship while embracing digital innovations? I’d love to hear varied perspectives as it seems this melding of old and new is truly shaping the future of miniature steam engineering.

Jasmine, your reflection on balancing traditional craftsmanship with modern tech really resonated with me. From my own experience, integrating precision 3D-printed components has been a game-changer in speeding up prototyping non-structural parts without compromising the tactile satisfaction of metalworking. Meanwhile, smart sensors hooked up to Raspberry Pi units add an educational layer, providing instant feedback on boiler pressure and temperature that’s difficult to gauge manually. I don’t feel this diminishes the hands-on connection; rather, it enhances understanding by blending intuition with data-driven insights. That said, it’s crucial to keep the core mechanical assembly strictly manual to preserve the craftsmanship essence. The marriage of old-school machining with IoT monitoring transforms the hobby into a hybrid of art and science — it feels like standing on the shoulders of giants while looking into the future. How do others strike this balance in their builds? Does anyone find that the tech integration perhaps distracts from the zen-like focus of purely manual metalworking, or have you found ways to harmonise both approaches effectively?

Building a miniature steam engine has always been a fascinating blend of craftsmanship and science. I’ve found that selecting the right materials, like brass for its machinability and steel for strength, really impacts the build process and the final performance. Recently, I experimented with using high-quality PTFE seals for my boiler, which drastically reduced leaks and improved safety. The precision needed for machining these tiny components is incredible, and I think advancements in CNC tooling have made it more accessible for hobbyists to achieve that intricate fit. I’m curious—how many of you incorporate thermodynamic principles into your design process? I’ve started running simulations to optimise boiler pressure and expansion ratios, which has been an eye-opener. Do others find that understanding the physics behind steam generation helps improve the efficiency of their models? Would love to see more discussion around balancing traditional craftsmanship with modern engineering tools to push the boundaries of miniature steam engines.