My First Encounter with Damascus Steel and Its Timeless Elegance

I’ll never forget the day I decided to try my hand at forging a Damascus steel letter opener. As a DIY enthusiast, I’ve always admired the intricate patterns and legendary strength of Damascus steel, which has a history dating back centuries. The idea of creating a functional piece that also serves as a work of art truly fascinated me. Inspired by articles I read about traditional blacksmithing techniques, I embarked on this project with a mix of excitement and a dash of nervousness.

Discovering the Art of Forging a Damascus Steel Letter Opener

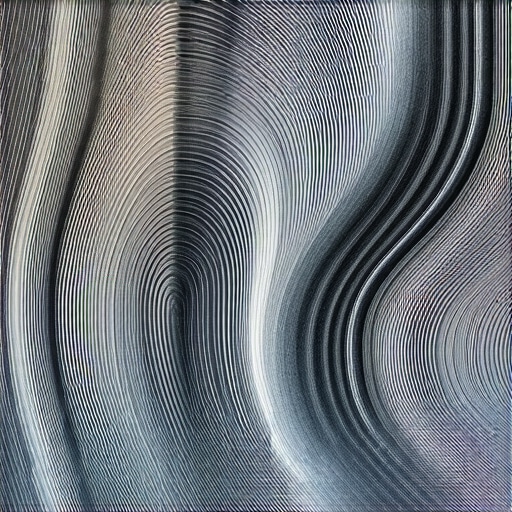

My journey began with sourcing the right materials. I learned that authentic Damascus steel is created through a process called pattern welding, involving layering different steels and forging them together. This process results in the signature swirling patterns that make each piece unique. I followed a detailed step-by-step guide to understand the nuances of forging, heat treating, and finishing.

Why a Damascus Steel Letter Opener Makes an Exceptional Gift

In my opinion, a handcrafted Damascus steel letter opener is more than just a tool; it’s a conversation piece and a symbol of craftsmanship. It’s ideal as a gift because it combines utility with artistry, making it suitable for professionals, collectors, or anyone who appreciates fine handmade objects. The process of making one also allows for personal customization, such as engraving initials or adding decorative handles, which adds an extra personal touch.

What Are the Challenges and Rewards of Forging Damascus Steel?

One challenge I encountered was maintaining the correct temperature during forging. Damascus steel requires precise heat control to achieve the desired patterns without compromising its strength. However, the reward of unveiling the swirling patterns after hardening and polishing made every effort worthwhile. I found that patience and attention to detail are essential. For those interested in honing their skills, I recommend exploring home improvement tips that involve metalworking techniques.

What makes a handcrafted Damascus steel piece truly special in a world of mass production?

In my view, it’s the personal touch and the craftsmanship involved. Each pattern is unique, telling a story of the forging process. Plus, knowing that it was made with care and skill adds sentimental value that mass-produced items simply cannot match.

If you’re inspired to try making your own Damascus steel item, I encourage you to start with small projects and gradually work your way up. Share your experiences or ask questions in the comments below—I love hearing about fellow DIYers’ journeys. For more creative ideas and expert tips, check out creative DIY crafts.

Mastering the Art of Damascus Steel Forging: A Deep Dive for DIY Enthusiasts

When exploring the craft of Damascus steel, understanding the intricate pattern welding process is essential. This technique involves layering different types of steel, then repeatedly heating, folding, and hammering to create the signature swirling patterns. As you refine your skills, it’s crucial to pay attention to temperature control during forging, as it directly impacts the pattern formation and the final strength of your piece. For those interested in honing their metalworking expertise, I recommend reviewing comprehensive home improvement tips that include advanced techniques in metal forging and heat treatment.

Choosing the Right Steel and Tools for Authentic Damascus

Authentic Damascus steel is created from high-carbon steels or a combination of different steels with varying properties. Using quality materials ensures durability and the ability to achieve detailed patterns. Essential tools include a reliable forge, a high-quality hammer, and a selection of chisels and tongs designed for high-temperature work. As an expert, I also suggest investing in a good anvil and protective gear to ensure safety and precision during your projects. Experimenting with different steel alloys can reveal unique pattern effects, making each piece truly one-of-a-kind.

Designing Functional and Artistic Damascus Items

While many DIYers focus on knives or letter openers, the potential of Damascus extends to creating jewelry, decorative panels, or even custom hardware. The key is balancing aesthetics with functionality. For example, a Damascus knife handle can be both a statement piece and ergonomic, enhancing your culinary or crafting experience. Personal customization, such as engraving or adding decorative elements, elevates your project from simple craft to art. For inspiration and step-by-step guidance, check out step-by-step guides tailored for all skill levels.

Overcoming Common Challenges in Damascus Steel DIY Projects

One common obstacle is achieving consistent patterning across multiple layers, which requires meticulous control of heating and forging speed. Additionally, cooling rates during quenching can influence the steel’s final properties, so understanding the science behind heat treatment is vital. As you gain experience, experimenting with different forging temperatures and cooling methods can lead to stunning results. Remember, patience and attention to detail are your best allies in this craft. For further insights into advanced metalworking techniques, I recommend exploring advanced DIY projects that push your skills to new levels.

How can a DIY blacksmith incorporate modern technology to enhance Damascus steel projects?

Integrating modern tools such as digital temperature controllers, laser-guided cutting tools, or even 3D modeling software can significantly improve precision and efficiency. For example, digital temperature controllers ensure consistent heat for pattern welding, reducing guesswork and enhancing pattern clarity. Additionally, 3D modeling helps design intricate handle fittings or decorative elements before physically creating them, saving time and materials. As technology advances, DIYers are increasingly blending traditional craftsmanship with innovative solutions, making projects more accessible and refined. Would you like to explore how to incorporate smart tools into your DIY metalworking journey? Feel free to share your ideas or ask questions in the comments. For more expert insights and creative inspiration, visit smart DIY solutions.

Reflections on the Intricacies of Damascus Steel and Personal Growth in Metalworking

As I delved deeper into the art of Damascus steel forging, I realized that mastering this craft is a continual journey of learning and refinement. Each project reveals new nuances—be it in pattern consistency, heat treatment, or finishing techniques—that challenge even seasoned blacksmiths. My personal experience has shown me that patience is not just a virtue but a necessity. For instance, achieving uniform layers during pattern welding requires meticulous control of heat cycles, which I have come to see as a delicate dance between science and artistry.

The Nuanced Science Behind Heat Treatment and Pattern Formation

Understanding the science behind heat treatment has profoundly impacted my ability to produce stunning patterns while ensuring the structural integrity of my Damascus steel pieces. When quenching, the cooling rate can significantly influence both the aesthetic swirl and the steel’s hardness. I often refer to authoritative sources such as home improvement tips on heat management techniques, which have been invaluable in fine-tuning my process. The interplay between temperature, forging speed, and cooling is complex, but mastering it transforms a simple billet into a work of art with resilience.

Personal Challenges and the Joy of Creative Experimentation

One of my ongoing challenges is ensuring pattern consistency across multiple layers, especially when experimenting with different steel alloys. Each alloy responds uniquely to heating and forging, necessitating a flexible yet disciplined approach. Overcoming these obstacles has been deeply rewarding. It reinforces the importance of meticulous record-keeping and reflective practice, which I recommend to any aspiring Damascus smith. Sharing these experiences in online forums or community groups fosters a sense of camaraderie and collective growth, which is essential in a craft that often feels solitary but is profoundly communal in spirit.

How Modern Technologies Can Enhance Traditional Damascus Techniques

Can integrating digital tools elevate the craftsmanship of Damascus steel forging?

Absolutely. Incorporating modern technology such as digital temperature controllers or laser-guided tools can greatly enhance precision. For example, a digital controller ensures consistent heat application, reducing variability and improving pattern clarity. Additionally, software like CAD can assist in designing intricate handle fittings or decorative accents before physically crafting them, bridging traditional techniques with digital innovation. I have personally experimented with these tools, and the results have been encouraging, inspiring me to push my boundaries further. For those interested, exploring smart DIY solutions can open new avenues for enhancing craftsmanship quality and efficiency.

Engaging with these advanced methods encourages a dialogue between tradition and innovation, enriching the craft and expanding creative possibilities. If you’re curious about integrating technology into your projects, I invite you to share your ideas or questions—collaborative learning accelerates mastery in this nuanced art form.

Refining Pattern Welding: From Technique to Artistry

Delving deeper into pattern welding, I discovered that meticulous layering and folding are crucial for creating intricate, unique patterns. Advanced blacksmiths often experiment with different steel alloys, such as 1095 and 15N20, to achieve contrasting colors and textures that enhance the visual appeal of Damascus steel. Achieving a seamless blend between these layers requires precise control over temperature and forging speed, which I’ve refined through iterative practice. Integrating techniques like differential heat treatment can also maximize the steel’s toughness while highlighting the patterns, transforming functional objects into stunning artworks.

Mastering Heat Treatment: Science Meets Artistic Expression

Understanding the science behind heat treatment enables a craftsman to manipulate the microstructure of steel for optimal results. For instance, precise quenching and tempering cycles influence not only the hardness but also the resilience of the final piece. I’ve found that controlling the cooling rate—using oil or polymer quenchants—can accentuate the pattern’s depth and contrast. Advanced techniques involve cryogenic treatment, which further refines the steel’s crystalline structure, yielding superior durability. For a comprehensive understanding, I recommend consulting authoritative sources such as home improvement tips that explore metallurgical science in depth.

Incorporating Digital Technology: Elevating Traditional Damascus Techniques

Can modern digital tools revolutionize the craft of Damascus steel forging?

Absolutely. The integration of digital temperature controllers ensures consistent heat application, leading to more predictable pattern formation. CAD software allows for detailed design of handle fittings or decorative elements before beginning the physical work, reducing material waste and enhancing precision. Laser-guided tools enable intricate detailing that was once difficult to achieve manually. I personally experimented with digital thermometers and found that they significantly improve pattern consistency, making complex designs more accessible for DIY enthusiasts. If you’re eager to incorporate these innovations, explore smart DIY solutions to enhance your craftsmanship.

Deepening Your Understanding: The Interplay of Craft, Science, and Innovation

Mastering Damascus steel forging is as much about understanding material science as it is about artistic expression. The nuanced control of heat cycles, the selection of steel alloys, and the use of cutting-edge tools all contribute to the final aesthetic and structural qualities. Each project becomes a personal laboratory, where experimentation leads to new pattern effects and improved resilience. Sharing these insights within communities fosters collaboration and innovation, pushing the boundaries of traditional blacksmithing. I invite you to explore advanced techniques and share your experiences—your journey may inspire breakthroughs in your craft.

< >

>

Things I Wish I Knew Earlier (or You Might Find Surprising)

Patience Is Your Best Friend

When I first started forging Damascus steel, I underestimated how crucial patience was. Rushing through heat cycles and pattern welding often led to inconsistent patterns and weaker steel. Taking my time, especially during heat treatment, made a huge difference in the final appearance and durability of my projects.

Material Quality Matters More Than You Think

Using high-quality steels like 1095 and 15N20 has transformed my results. Cheaper steels tend to warp or fail during forging, which was frustrating at first. Investing in good materials pays off in the strength and beauty of your Damascus pieces.

Modern Tools Can Elevate Your Craft

Incorporating digital temperature controllers and CAD software has opened new possibilities for me. These tools help achieve more precise patterns and consistent heat, reducing guesswork and enhancing the overall quality of my work. It’s amazing how technology can complement traditional blacksmithing techniques.

Don’t Be Afraid to Experiment

Trying different steel alloys, forging techniques, or even decorative handle designs keeps the craft exciting. Some of my most striking patterns came from accidental experiments, reminding me that creativity is key in Damascus steel forging.

Community Support Is Invaluable

Sharing my progress and challenges with online communities has provided encouragement and expert tips. Learning from others’ experiences accelerates growth and makes the journey more enjoyable. I highly recommend engaging with fellow DIYers for inspiration and advice.

Resources I’ve Come to Trust Over Time

- Bladesmith’s Forum: An active community where experienced blacksmiths share insights, troubleshooting tips, and project ideas. It’s been my go-to for honest feedback and inspiration.

- KnifeMaker’s Magazine: Offers detailed articles on metallurgy, heat treatment, and pattern welding techniques. It’s a treasure trove of knowledge for both beginners and advanced smiths.

- Instructables Damascus Steel Projects: Provides step-by-step guides tailored for DIY enthusiasts, making complex techniques more accessible. I’ve learned a lot from their practical tutorials.

- Modern Blacksmithing Books: Classics like “The Complete Bladesmith” by Jim Hrisoulas have deepened my understanding of metallurgy and craftsmanship. They’re worth every penny if you want to master the science behind the art.

Parting Thoughts from My Perspective

Creating Damascus steel pieces has been a journey of discovery, patience, and personal growth. The blend of science, craftsmanship, and artistry makes it a rewarding craft that continually challenges and inspires me. If you’re passionate about DIY projects and eager to learn a skill that combines tradition with innovation, forging Damascus steel might just be your next exciting adventure. Remember, every pattern tells a story—yours could be the next masterpiece. If this resonated with you, I’d love to hear your thoughts. Feel free to share your experiences or ask questions in the comments, and don’t forget to check out home improvement tips for more DIY inspiration.