My First Encounter with Wooden Gears: A Spark of Inspiration

It all started on a rainy weekend when I stumbled upon a fascinating YouTube video about intricate wooden kinetic sculptures. The mesmerizing motion of gears and levers captivated me instantly, igniting a desire to create my own complex wooden toy. As an avid DIY enthusiast, I knew that building such a toy would be both challenging and rewarding, blending craftsmanship with mechanical ingenuity.

Designing the Blueprint: Balancing Art and Engineering

Before diving into the woodworking, I spent hours sketching out the design. I wanted a toy that was not only visually appealing but also mechanically intricate enough to entertain all ages. I researched various gear ratios and lever mechanisms, ensuring smooth operation. This phase reminded me of the importance of planning, much like designing a miniature engine. For inspiration, I turned to authoritative sources such as step-by-step DIY guides that helped me understand the fundamentals of gear trains.

Choosing the Right Materials and Tools

Wood selection was critical. I opted for hardwoods like oak and maple for durability, knowing that the moving parts would endure repeated motion. Precision tools such as fine saws, chisels, and sanders were essential. I also learned that patience was key; every cut and fit needed to be exact to ensure the gears meshed perfectly. This meticulous process reminded me of the craftsmanship involved in advanced woodworking techniques.

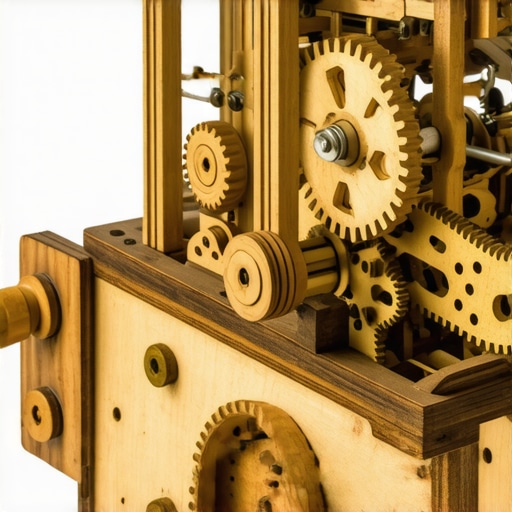

Assembling the Kinetic Marvel: Patience and Precision

Assembly was akin to solving a complex puzzle. I started by constructing the base frame, then carefully attached the gear wheels and levers. Ensuring smooth rotation required adjusting the gear teeth and verifying alignment frequently. I encountered some setbacks, like gears not turning freely, which taught me the importance of fine-tuning and testing. The thrill of watching the gears engage flawlessly was worth every effort. I recommend fellow DIYers to document each step, making future adjustments easier.

What Makes a Wooden Kinetic Toy Truly Engaging?

Why do intricate gear mechanisms captivate both children and adults?

The beauty of a complex wooden gear toy lies in its ability to blend simple mechanics with artistic design. It embodies a timeless fascination with motion and craftsmanship. As I observed the toy in motion, I felt a connection to traditional craftsmanship and modern engineering. Such projects foster patience and problem-solving skills, making them perfect for all ages. For more inspiration, explore creative DIY crafts that celebrate mechanical artistry.

If you’re inspired to create your own wooden gears and levers toy, I encourage you to start small, learn from each step, and enjoy the process. Feel free to comment below with your experiences or questions. Sharing our DIY journeys enriches the community and sparks new ideas!

Unlocking the Secrets of Precision in Wooden Gear Construction

Creating a sophisticated wooden gear toy demands not only patience but also a deep understanding of mechanical principles. As an experienced DIY enthusiast, I emphasize the importance of meticulous measurements and selecting the right gear ratios to ensure smooth operation. Fine-tuning the gear teeth alignment can make the difference between a toy that runs flawlessly and one that stalls. For those eager to deepen their understanding, exploring authoritative resources like advanced woodworking techniques can provide invaluable insights into precision craftsmanship.

Material Mastery: Choosing and Working with Quality Woods

While common woods like oak and maple are excellent choices, understanding the grain orientation and moisture content is crucial for durability and smooth functioning. I recommend experimenting with laminated layers for added strength or incorporating contrasting woods for aesthetic appeal. Using specialized tools such as fine-toothed saws, micro chisels, and calibrated sanders allows for achieving the perfect fit. Remember, the devil is in the details, and mastering material preparation is key to professional-looking results.

Designing with Artistic and Mechanical Harmony

When designing your gear mechanism, consider both the visual appeal and the mechanical efficiency. Incorporating decorative elements like carved motifs or engraved patterns can elevate the aesthetic, but they should not compromise structural integrity. I often sketch multiple iterations, adjusting gear sizes and lever placements to optimize motion flow. For inspiration and step-by-step guidance, check out comprehensive DIY guides that help bridge the gap between theory and practice.

Expert Tips for Troubleshooting and Refinement

Gears that don’t turn smoothly often stem from slight misalignments or uneven teeth. I recommend assembling the gear train in stages, testing each component before proceeding. Using a magnifying glass can help identify tiny imperfections, while applying a light coating of beeswax or specialized lubricant reduces friction. If issues persist, revisiting your gear ratios or adjusting the gear tooth profiles may be necessary. Documenting each step with photos or sketches can facilitate troubleshooting and future modifications.

What Makes a Wooden Gear Toy Not Just Engaging, but Truly Inspiring?How can intricate gear mechanisms foster creativity and technical skills in DIY enthusiasts?

In my experience, complex gear toys serve as a perfect convergence of art and engineering. They challenge builders to think critically about motion, force, and material behavior, nurturing problem-solving skills. Moreover, the satisfaction derived from witnessing your creation come to life through precise mechanical interactions is unmatched. These projects also promote patience and perseverance, qualities essential in any DIY journey. If you’re interested in expanding your skills, exploring creative DIY crafts can inspire innovative approaches to mechanical design.

Feel free to share your experiences or ask questions in the comments below—your insights can motivate others and spark new ideas in our thriving DIY community!

Refining Your Craft: Embracing the Challenges of Precision and Artistic Vision

As I continued my journey into the intricate world of wooden gear construction, I found that every successful project became a testament to patience and meticulous attention to detail. The process of aligning gear teeth and ensuring smooth meshing is not merely about technical accuracy but also about embracing the artistry of mechanical harmony. This journey taught me that perfection often lies in small adjustments—sandings, fine-tuning gear ratios, and even reconsidering the aesthetic elements to harmonize form and function seamlessly.

Personal Insights: Balancing Functionality with Artistic Expression

One of the most rewarding aspects of creating kinetic wooden toys is the ability to infuse personality into each piece. Whether it’s through decorative carvings, engraved patterns, or contrasting woods, these elements elevate a simple gear train into a work of art. I recall experimenting with layered woods to produce a striking visual effect while maintaining mechanical integrity. This duality—where engineering meets design—requires a keen eye and an understanding that every detail influences the overall experience. For those venturing into this craft, I recommend exploring advanced woodworking techniques, as they can open new avenues for creativity (see here).

Deeper Questions: How Do Material Properties Influence Gear Performance?

What nuances in choosing woods or composites can impact the durability and efficiency of your gear mechanisms?

In my personal experience, understanding the grain orientation and moisture content of your materials is crucial. Hardwoods like oak and maple are excellent for durability, but their grain structures can vary, affecting how gears wear over time. Laminated layers can reinforce structural integrity, while contrasting woods can add aesthetic appeal—each choice influencing performance and longevity. Exploring innovative materials, like engineered woods or composites, might offer improved stability or reduced friction, which is vital for high-precision projects (more insights here).

Invitation to Share Your Creative Journeys

Building complex wooden gear systems is a deeply personal and rewarding craft. I encourage you to share your experiences, challenges, and successes—whether through comments or your own blog posts. Our collective knowledge and shared passion can inspire new techniques and innovations, pushing the boundaries of what we can achieve with traditional woodworking and mechanical design. If you’re looking for further inspiration or guidance, don’t hesitate to explore other creative DIY projects, like unique home decor crafts, to expand your creative horizons.

The Nuances of Material Science in Wooden Gear Durability

As I delved deeper into the realm of high-precision wooden gear assemblies, I realized that mastering material properties is paramount. Understanding how grain orientation, moisture content, and even natural defects influence gear longevity has transformed my approach. For instance, selecting quarter-sawn hardwoods minimizes warping and ensures consistent gear meshing over time. Additionally, exploring engineered woods or composite materials, such as laminated veneer lumber, offers enhanced stability and reduced friction—crucial factors for intricate gear trains. These insights, supported by research from industry leaders like Woodworking Network, have propelled my craftsmanship to new heights, allowing me to create gear systems that are both durable and aesthetically refined.

How can understanding the microstructure of woods influence the precision of gear teeth manufacturing?

Deep knowledge of wood microstructure enables me to anticipate wear patterns and optimize gear tooth profiles for smoother operation. For example, aligning gear teeth along the grain reduces internal stresses, preventing premature failure. Advanced techniques such as micro-milling and laser engraving can achieve extremely fine gear teeth with minimal imperfections, similar to CNC methods used in industrial settings, but adapted for woodworking. The key is meticulous material selection and preparation—experimenting with laminated layers or contrasting woods for visual contrast and structural strength. If you’re keen to elevate your projects, exploring resources like advanced woodworking techniques can offer invaluable guidance on precision craftsmanship.

Design Optimization for Mechanical Efficiency and Artistic Expression

Balancing mechanical function with artistic design is a challenge I embrace wholeheartedly. Incorporating decorative carvings or inlays into gear hubs not only enhances visual appeal but also requires careful structural considerations. I often employ CAD software to simulate gear motion and aesthetic integration before commencing physical work, ensuring that artistic embellishments do not compromise mechanical efficiency. This iterative process allows me to refine gear ratios and lever placements, optimizing motion fluidity while maintaining a personalized touch. Exploring complex design software and techniques, such as layered laser-cut patterns, can unlock new creative potentials, bridging the gap between art and engineering. Discover more at comprehensive DIY guides for detailed strategies on harmonizing form and function.

Invitation to Share Your Advanced DIY Mechanical Art

If you’ve ventured into high-precision wooden gear crafting, I invite you to share your insights, challenges, and innovations. Engaging with a community of passionate makers accelerates collective learning and sparks inspiration. Whether you’re experimenting with novel materials, intricate gear ratios, or artistic embellishments, your journey contributes profoundly to the craft. Feel free to connect through comments or personal blogs—your experiences can inspire others to push the boundaries of traditional woodworking and mechanical artistry. For further advanced techniques, consider exploring digital design methods that complement physical craftsmanship and open new creative horizons.

Things I Wish I Knew Earlier (or You Might Find Surprising)

The Power of Patience

One of the most underestimated aspects of working with wooden gears is patience. When I first started, I thought precision would come quickly, but I soon realized that meticulous measurements and gentle adjustments are what ultimately bring your creations to life. Rushing often leads to misaligned gears or uneven teeth, which can stall your project, so take your time and enjoy each step.

The Material Matters More Than You Think

Choosing the right wood isn’t just about aesthetics; it deeply influences performance. I learned that hardwoods like oak or maple provide better durability and smoother gear meshing, whereas softer woods tend to wear out faster. Experimenting with laminated layers can also add strength and reduce warping, transforming your project from good to professional-looking.

Designing Is an Art and Science

Balancing visual appeal with mechanical function requires a delicate touch. I often sketch multiple iterations, adjusting gear sizes and lever placements to optimize motion. Incorporating artistic elements like carved motifs or contrasting woods elevates the piece, but always keep the mechanical harmony in mind. CAD software can be a game-changer here, allowing you to simulate before building.

Small Adjustments Make a Big Difference

Fine-tuning gear teeth alignment and gear ratios is essential for smooth operation. I found that even tiny imperfections can cause stalling or jerky movement. Using a magnifying glass and lubricants like beeswax helped me achieve silky-smooth motion. Documenting each tweak with photos made future refinements much easier.

The Joy of Creating Mechanical Art

What truly makes wooden gear toys captivating is their ability to blend craftsmanship with artistic expression. They challenge your mind and reward your patience with mesmerizing movement. Sharing your progress and exchanging tips with fellow DIY enthusiasts can spark new ideas and push your skills further.

Resources I’ve Come to Trust Over Time

First, I highly recommend exploring comprehensive DIY guides that provide detailed instructions suitable for all skill levels, helping you grasp the fundamentals and advanced techniques. For material insights, Woodworking Network offers industry-leading articles on wood properties and best practices. Lastly, to refine your design skills, check out advanced woodworking techniques, which delve into precision and artistic techniques that elevate your projects.

Parting Thoughts from My Perspective

Creating intricate wooden gears has been one of the most fulfilling journeys I’ve embarked on, teaching me patience, craftsmanship, and artistic vision. The key takeaway is that every small detail counts—whether it’s selecting the perfect wood, fine-tuning gear teeth, or adding decorative touches. If you’re passionate about blending art and engineering, I encourage you to start your own project, embrace the learning curve, and savor each success. Feel free to share your experiences or ask questions—I’d love to hear your thoughts and inspire each other on this rewarding craft journey!