My Journey into Sustainable Food Preservation

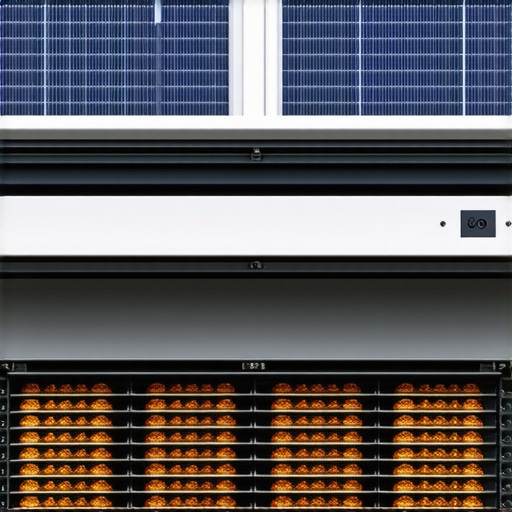

Last summer, I decided to take my gardening and eco-conscious lifestyle to the next level by building a solar food dehydrator. As someone passionate about sustainability and reducing waste, I was excited to craft a device that would allow me to preserve my harvest using only upcycled components and the power of the sun. This project turned out to be a rewarding blend of DIY ingenuity and environmental responsibility.

Why I Chose Upcycled Materials for My Solar Dehydrator

In my research, I learned that many traditional food dehydrators can be quite energy-intensive and expensive. By opting for upcycled parts—like old aluminum windows, scrap wood, and repurposed fans—I could minimize waste and create a truly eco-friendly solution. Plus, using recycled materials adds a unique charm and character to the final product. For detailed step-by-step guidance, I found this DIY guide invaluable.

Designing My Solar Food Dehydrator: Personal Insights

I started by designing a simple, ventilated box that could maximize solar heat absorption. I used an old wooden pallet as the frame, ensuring it was sturdy yet lightweight. The crucial component was sourcing a transparent panel, which I repurposed from an old greenhouse window. This allowed sunlight to enter while trapping heat inside. I also upcycled an exhaust fan from an old computer to promote airflow, vital for even drying. The process was a fun challenge in balancing insulation with ventilation, and I enjoyed experimenting with different configurations.

What Are the Key Challenges in DIY Solar Food Dehydrator Projects?

One challenge I faced was maintaining consistent airflow and temperature, especially on cloudy days. To address this, I added adjustable vents and used a simple solar thermometer to monitor heat levels. Another consideration was ensuring the materials were food-safe and weather-resistant. I sealed all wood with natural oils and avoided plastics that could leach chemicals. This project reinforced my belief that with a little creativity, sustainable living can be both practical and enjoyable.

If you’re considering building your own solar food dehydrator, I highly recommend exploring online communities and expert blogs for tips and troubleshooting advice. Sharing our experiences helps us all learn and improve our eco-friendly projects.

Would you try upcycling components for your next DIY project? Feel free to share your ideas or ask questions in the comments below—I love exchanging eco-conscious tips!

Mastering the Art of Crafting a DIY Solar Food Dehydrator Using Upcycled Materials

Building a solar food dehydrator with upcycled components is not only a rewarding project but also a practical way to enhance your sustainable living practices. As an expert, I’ve seen how thoughtful design and careful material selection can significantly improve efficiency and durability. The key lies in understanding the intricacies of solar heat management and airflow control, which are crucial for consistent dehydration results.

Design Strategies for Optimal Solar Heat Capture and Airflow

One of the most common challenges in DIY solar dehydrator projects is achieving uniform heat distribution while maintaining effective airflow. To tackle this, I recommend designing a ventilated chamber with adjustable vents at both the intake and exhaust points. Using natural convection principles, you can enhance airflow without mechanical fans—though repurposing an old computer fan, as I did, can provide additional control during cloudy days. Incorporating reflective surfaces inside the enclosure can also amplify solar gain, making use of materials like aluminum foil or reflective paint. For further insights into designing efficient solar dehydrators, check out this DIY guide.

Material Selection: Balancing Sustainability and Performance

Choosing the right materials is fundamental. Reclaimed wood, such as pallets or scrap lumber, offers a sturdy, eco-friendly frame, but it must be sealed with natural oils or beeswax to prevent weather damage and ensure food safety. The transparent cover is critical; old greenhouse panels, polycarbonate sheets, or even repurposed glass windows provide excellent solar transmission. Insulation is another aspect where upcycled materials shine—recycled denim or wool can provide thermal barriers without introducing harmful chemicals. Remember, the durability of your materials directly impacts the longevity of your dehydrator, so always prioritize weather-resistant options.

What Are the Hidden Complexities in DIY Solar Food Dehydrator Design?

Beyond basic construction, experts recognize the importance of controlling internal microclimates to prevent spoilage and ensure even drying. This includes managing humidity levels inside the chamber and preventing heat loss during cloudy periods. Incorporating a simple hygrometer or moisture sensor can offer real-time data, guiding adjustments to vents or supplemental heating sources. Additionally, selecting food-safe, non-toxic paints and sealants is vital. For those interested in integrating smart technology, installing low-cost sensors and automated vents can optimize performance, transforming a simple project into an advanced eco-friendly appliance. For a detailed walkthrough on designing such systems, explore this smart DIY solutions article.

Engaging with online communities and expert blogs can reveal innovative techniques and troubleshooting tips, making your project more successful. Sharing your progress and learning from others accelerates mastery and promotes sustainable innovation.

Have you considered how integrating automation or advanced materials could elevate your DIY solar dehydrator? Feel free to share your ideas or ask questions below—exchanging knowledge helps us all grow in eco-conscious craftsmanship!

Balancing Complexity and Practicality in Solar Dehydrator Design

When I first embarked on building my solar food dehydrator, I was captivated by the idea of marrying sustainability with efficiency. Over time, I realized that achieving optimal performance isn’t just about repurposing materials; it requires a nuanced understanding of thermal dynamics and airflow management. One critical aspect I learned is the importance of creating a microclimate within the dehydrator that promotes even drying without excessive energy loss.

Deep Dive into Microclimate Control

Managing humidity and temperature fluctuations inside the chamber is a subtle art. I experimented with incorporating natural hygrometers and moisture sensors, which allowed me to monitor internal conditions in real-time. This data enabled me to fine-tune adjustable vents, balancing intake and exhaust to maintain a steady environment. Such precision not only improves drying consistency but also extends the lifespan of delicate produce like herbs or thinly sliced fruits.

Integrating Smart Technology for Enhanced Performance

Inspired by smart home innovations, I explored integrating automated sensors and vent controls. Using open-source microcontrollers like Arduino or Raspberry Pi, I set up systems that responded to real-time sensor data, adjusting vents automatically to optimize airflow and temperature. This approach transformed my simple dehydrator into a semi-automated, high-efficiency unit, all while maintaining a commitment to upcycled components.

What Are the Challenges in Automating a DIY Solar Dehydrator?

Automation introduces complexities such as power management for sensors and actuators, ensuring weatherproofing of electronic components, and balancing energy consumption with performance gains. Ensuring food safety remains paramount; all materials and enclosures must be non-toxic and food-safe. Moreover, integrating technology should not compromise the simplicity and eco-friendliness that make DIY projects rewarding. To navigate these challenges, I relied on detailed guides from smart DIY solutions and experimented with modular designs that allow easy maintenance and upgrades.

Exploring these advanced techniques deepened my appreciation for how thoughtful engineering can elevate sustainable DIY projects. I invite you to share your experiences with automation or complex design tweaks—your insights might inspire others to push the boundaries of eco-friendly craftsmanship. If you’re interested in further enhancing your projects, check out related guides on home improvement tips and DIY solutions for beginners.

Refining Microclimate Management: Precision Control for Optimal Drying

Achieving consistent dehydration results hinges on meticulous microclimate regulation within the dehydrator. I discovered that integrating sophisticated sensors, such as digital hygrometers and temperature loggers, allows for nuanced monitoring of internal humidity and heat levels. By pairing these with adjustable vents, I can dynamically respond to fluctuating weather conditions, ensuring stable drying environments. This approach not only enhances product quality but also prolongs the lifespan of delicate produce like herbs and sliced fruits. Implementing data-driven adjustments transforms a basic DIY project into a precision eco-technology system.

Harnessing Open-Source Automation: Smart Vents and Energy Efficiency

Building upon my initial manual controls, I ventured into automating vent operation using microcontrollers, such as Arduino and Raspberry Pi. These platforms facilitate real-time responses to sensor data, enabling automated vent adjustments that optimize airflow without manual intervention. Incorporating solar-powered sensors ensures the system remains energy-efficient and sustainable. Additionally, utilizing open-source coding communities allows for customized firmware, tailored to specific climate conditions. This automation elevates the dehydrator from a simple solar device to a smart, self-regulating system, exemplifying how advanced DIY techniques can merge sustainability with technological innovation.

Advanced Material Selection: Durability and Food Safety in Complex Environments

Material choice becomes even more critical when integrating automation and microclimate control. I recommend utilizing weather-resistant, food-safe materials like silicone-sealed reclaimed wood, UV-stabilized polycarbonate for transparent covers, and non-toxic, reflective insulation options such as recycled wool or denim. These materials withstand the rigors of outdoor exposure while maintaining safety standards. The careful selection and treatment of components ensure longevity and performance, especially when exposed to variable environmental conditions. Consulting authoritative sources like the DIY technical guides helps refine these choices, balancing sustainability with technical robustness.

How Can Integrating Smart Technology Elevate DIY Solar Dehydrators to Industrial Standards?

Embedding smart sensors and automated systems can elevate your dehydrator to near-industrial efficiency. By employing IoT-enabled modules, you can remotely monitor internal conditions, receive alerts, and adjust settings via smartphone apps. This seamless integration allows for precise dehydration cycles, resource conservation, and real-time troubleshooting. Such enhancements require thoughtful engineering but offer unparalleled control and sustainability benefits. I encourage enthusiasts to explore open-source projects and community forums for innovative solutions, sharing insights to push the boundaries of eco-friendly craftsmanship. For further inspiration, visit smart DIY solutions for detailed guidance and project ideas.

Things I Wish I Knew Earlier (or You Might Find Surprising)

The Hidden Complexity of Upcycled Materials

One thing I underestimated initially was the importance of selecting truly weather-resistant and food-safe upcycled materials. I once used reclaimed wood that looked perfect but quickly warped when exposed to outdoor humidity, reminding me to prioritize durability and safety above aesthetics. This experience taught me to scrutinize recycled materials more carefully, ensuring they can withstand the elements and won’t leach harmful substances into my preserved foods.

The Subtle Art of Microclimate Management

Managing internal humidity and temperature was trickier than I anticipated. I thought a simple vent would suffice, but I soon realized that small adjustments—like reflective surfaces or moisture sensors—could dramatically improve drying consistency. Incorporating these subtle controls made a significant difference, especially during unpredictable weather, and helped me produce better-quality dried goods.

The Power of Automation and Sensors

Experimenting with microcontrollers like Arduino to automate vent adjustments opened a new world of efficiency. It was surprising how small tech integrations could turn a basic solar dehydrator into a semi-smart system, maintaining optimal conditions with minimal manual effort. This innovation not only saved time but also improved drying results, proving that eco-friendly projects can embrace smart solutions without sacrificing sustainability.

Balancing DIY Complexity With Practicality

I learned that over-engineering can sometimes backfire. Striving for perfection in airflow and insulation led to added complexity, which made maintenance cumbersome. Striking a balance between effective design and simplicity made my dehydrator more reliable and easier to use day-to-day, highlighting that practical DIY often benefits from a minimalist approach.

My Personal Reflection: The Joy of Sustainable Innovation

Building a solar food dehydrator from upcycled components was more than just a project; it became a journey of learning and experimentation. It reinforced that sustainable living is a continuous process of discovery—sometimes through trial and error. If you’re passionate about eco-friendly crafts, I encourage you to embrace these challenges, as they lead to the most rewarding results. Remember, every small step counts toward a more sustainable future, and sharing your experiences can inspire others on the same path.

Resources I’ve Come to Trust Over Time

DIY Kutak’s Step-by-Step Guides

This site offers comprehensive, easy-to-follow instructions perfect for all skill levels. I’ve found their guides invaluable for troubleshooting and refining my projects, especially when experimenting with complex systems like microclimate control.

Smart DIY Solutions by DIY Kutak

Their insights into integrating affordable automation and sensor technology have been eye-opening. They provide practical advice that bridges the gap between simple DIY and smart tech, making innovation accessible to enthusiasts.

Home Improvement Tips on DIY Kutak

For tips on optimizing airflow, insulation, and weatherproofing, this resource has been my go-to. It helps me ensure my projects are not only functional but also durable and safe for long-term outdoor use.

Community and Forums

Engaging with online DIY communities has exposed me to a wealth of real-world experiences and creative solutions. Sharing ideas and troubleshooting tips fosters a supportive environment that accelerates learning and innovation.

Parting Thoughts from My Perspective

Crafting a DIY solar food dehydrator with upcycled components has been a deeply rewarding experience. It’s a perfect example of how sustainable living combines creativity, technology, and environmental responsibility. The journey taught me that patience and continuous learning are key—every challenge is an opportunity to improve. If this resonates with you, I’d love to hear your thoughts, or feel free to share your own adventures in eco-friendly DIY projects. Let’s keep inspiring each other toward a greener, more resourceful future!

I really appreciate the thoughtful approach to using upcycled materials! It’s inspiring to see how common items like old greenhouse panels and computer fans can be repurposed effectively for sustainable projects. The point about managing microclimates really resonated with me — controlling humidity and temperature is indeed tricky but crucial for consistent drying results. I’ve tried similar DIY dehydrators, and I found adding simple reflective surfaces inside really helps boost solar gain. One challenge I’ve faced is weatherproofing and ensuring the materials stay durable over time, especially in variable climates. Have others found particular sealing techniques or treatments that work well for keeping reclaimed materials weather-resistant without compromising food safety? I’m curious about your experiences or tips for maintaining long-term performance. Overall, this project reminds me that balancing ingenuity with practical safety considerations makes for a rewarding DIY experience. I’d love to hear more about how you keep your dehydrator weatherproof while still using upcycled components.