Discovering My Passion for DIY Wooden Toys: A Personal Journey

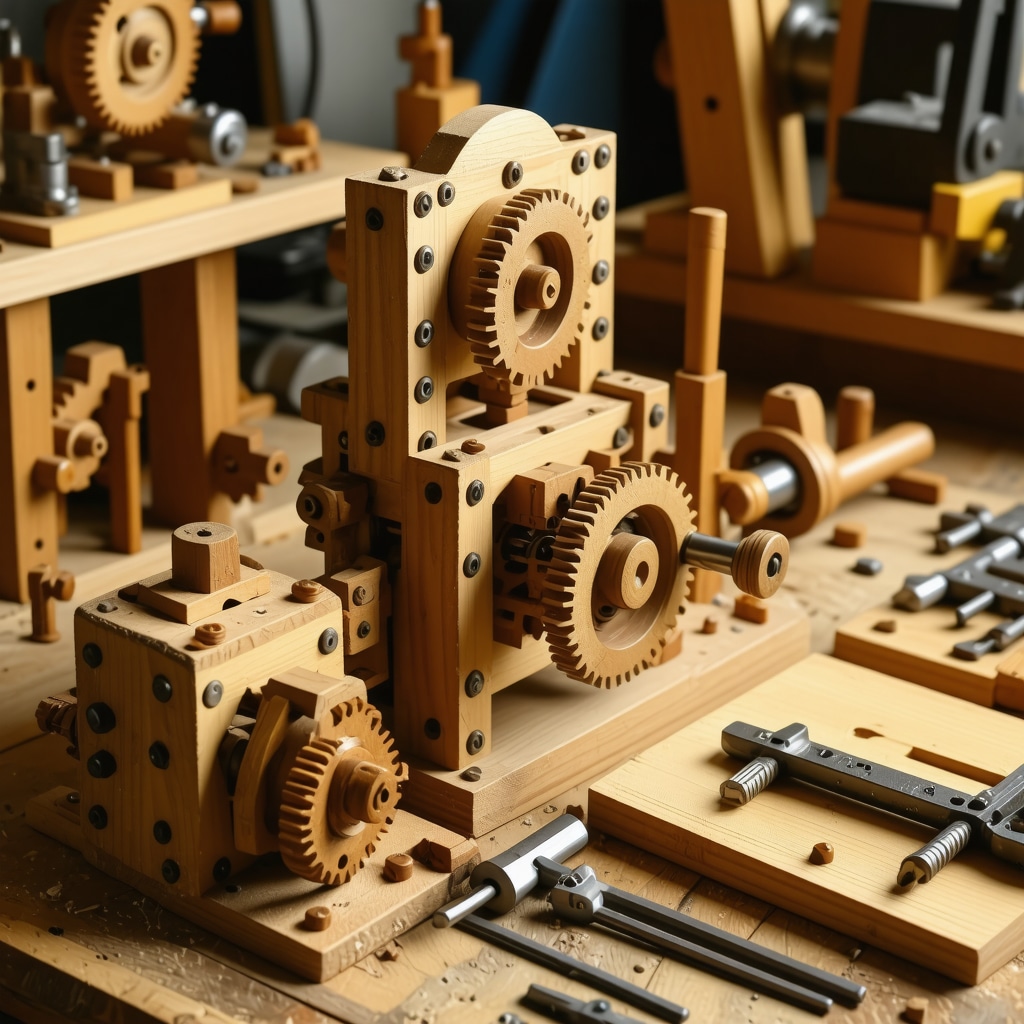

It all started when I stumbled upon a simple wooden gear toy at a local craft fair. That tiny, intricate mechanism sparked my curiosity and ignited a passion for creating complex kinetic wooden toys myself. Over the years, I’ve learned that building these toys isn’t just about craftsmanship; it’s about understanding the fascinating interplay of gears, levers, and motion. Today, I want to share my experience and insights on crafting these engaging and educational wooden masterpieces.

Why Building Complex Wooden Toys with Gears & Levers Became My Favorite Hobby

As someone who loves both woodworking and mechanical puzzles, I found that combining these passions yields incredibly rewarding projects. Building a kinetic wooden toy with gears and levers challenges my problem-solving skills while allowing me to create something both beautiful and functional. Plus, it’s a wonderful way to introduce kids and beginners to the basics of mechanical engineering, fostering curiosity and creativity. I often consult resources like step-by-step DIY guides to refine my techniques.

How I Designed and Assembled My First Kinetic Wooden Puzzle

My first project involved designing a simple gear train that powered a lever mechanism. I selected high-quality hardwoods like maple and oak for durability and aesthetic appeal. Using precision tools, I carved the gears with interlocking teeth, ensuring smooth motion. The key was to pay attention to tolerances—too tight or too loose would ruin the mechanism’s function. I also incorporated levers that amplified the gear movement, making the toy more dynamic. The process taught me patience and precision, essential skills in woodworking and mechanical design.

What Are the Essential Skills and Tools for Building Such Toys?

Creating complex kinetic wooden toys requires a mix of woodworking, mechanical understanding, and patience. Basic tools like scroll saws, routers, and sanders are indispensable. Additionally, understanding gear ratios and lever mechanics is crucial. I often refer to online tutorials and forums—like this soundproofing project—to improve my skills and troubleshoot issues. Mastery of these skills allows me to craft intricate toys that move smoothly and last for generations.

Why Do I Believe Building Wooden Toys Is More Than Just a Hobby?

For me, constructing these kinetic toys is a form of mindful craftsmanship that connects me to a tradition of handmade artistry. It’s also a fantastic way to teach children about mechanics and engineering in a hands-on manner. Plus, the satisfaction of seeing a project come to life through patience and skill is unparalleled. If you’re interested in exploring similar projects, I recommend checking out DIY projects for beginners.

If you’ve ever built or considered building a wooden gear toy, I invite you to share your experiences or ask questions below. Creating these toys is not just about the finished product but also about enjoying the process of learning and crafting.

Unlocking the Secrets of Precision: Advanced Techniques in Wooden Gear Crafting

Building intricate wooden gears and levers demands a keen eye for detail and mastery of woodworking techniques. As an expert, I emphasize the importance of selecting the right materials—hardwoods like maple, cherry, or walnut provide durability and fine grain, essential for precise gear teeth. Employing high-precision tools such as scroll saws with fine blades and rotary tools allows for cleaner cuts and intricate detailing. To achieve perfect interlocking, I often use digital calipers for measuring tolerances meticulously, ensuring smooth, frictionless motion in my designs.

Design Strategies for Complex Kinetic Wooden Toys

Designing these toys starts with sketching detailed blueprints that account for gear ratios, lever mechanics, and overall motion flow. Software like CAD can aid in visualizing complex assemblies before physical construction, reducing errors and material waste. When crafting the gears, I focus on the gear tooth profile, often choosing involute shapes for optimal meshing. Integrating levers with amplified movement requires an understanding of mechanical advantage—this is where experimenting with different lever arm lengths and pivot points becomes crucial. For inspiration and technical guidance, exploring resources such as soundproofing strategies can offer valuable insights into precision craftsmanship.

Practical Tips for Assembling and Testing Wooden Mechanical Systems

Assembly should be done gradually, verifying each gear mesh and lever action before proceeding. I recommend using fine-grit sandpaper to smooth gear teeth and pivot points to reduce friction. Lubrication with natural oils like beeswax or mineral oil enhances movement without compromising the wood. Testing the toy involves observing for any binding or slipping, which signals the need for fine adjustments. Implementing a systematic approach—adjusting gear meshing, verifying lever pivots, and ensuring alignment—can significantly improve the final performance. For those eager to explore beginner projects, I advise starting with simple gear trains and progressively increasing complexity, as detailed in DIY projects for beginners.

How Can I Innovate Traditional Wooden Gear Designs for Modern Mechanical Toys?

Innovation often stems from blending traditional craftsmanship with modern technology. Using computer-aided design (CAD) software allows for complex gear configurations and custom tooth profiles that are difficult to achieve manually. Additionally, integrating sustainable materials—such as bamboo or reclaimed wood—can add eco-friendly appeal. Experimenting with different gear arrangements, like planetary gear systems or compound gear trains, can unlock new motion possibilities. For example, creating multi-axis gear systems can produce more dynamic and engaging toys, appealing to both children and adult enthusiasts. To deepen your understanding, exploring advanced techniques in goldwork embroidery can inspire detailed craftsmanship and artistic expression in your projects.

If you’re passionate about enhancing your skills or have unique ideas for kinetic wooden toys, I encourage you to share your thoughts below or explore more about creative DIY crafts to broaden your creative horizons.

Refining Precision: The Subtleties of Material Selection and Finish

As I delved deeper into crafting complex wooden gears, I discovered that the choice of wood is not just about durability but also about grain quality and finish. Hardwoods like cherry or walnut aren’t just aesthetically pleasing; they also offer tight, consistent grain structures that facilitate precise gear teeth and minimal friction. Achieving a flawless finish involves multiple sanding stages—starting from coarse grit and progressing to ultra-fine micro abrasives—culminating in a smooth surface that reduces wear over time. I’ve found that applying natural oils or waxes not only enhances the appearance but also provides a subtle lubrication, ensuring that the gears turn seamlessly without squeaks or sticking. This meticulous attention to surface detail transforms a good project into a lasting heirloom.

Innovative Gear Profiles and Tooth Geometry

Traditional involute gears are a staple in wooden toy design, but exploring alternative tooth geometries can unlock new motion dynamics. For example, implementing cycloidal or custom-crafted tooth profiles can improve meshing efficiency and reduce backlash. Using CAD software like Fusion 360 allows me to experiment with these profiles digitally before committing to the wood. When I cut these profiles with my scroll saw or CNC router, the accuracy is paramount. I often refer to advanced references like expert guides on mechanical design to fine-tune my tooth shapes. These innovations, though subtle, significantly enhance the fluidity and realism of kinetic wooden toys, making them more engaging and sophisticated.

Leveraging Mechanical Advantage for Complex Motion

One of the most rewarding challenges is designing levers and linkages that amplify motion or produce intricate movement patterns. This involves understanding mechanical advantage—how the length of a lever arm or the pivot position influences force and motion. I often incorporate multiple lever systems within a single toy, allowing a small input force to generate large, captivating movements. For example, a lever connected to a gear train might activate a series of cascading motions, creating a mesmerizing sequence. Achieving this requires precise measurements and iterative testing, often with tiny adjustments to pivot points or arm lengths. I’ve learned that the key to success lies in patience and a willingness to experiment—sometimes, a small change can dramatically improve the toy’s performance.

How Can I Incorporate Modern Technology into Traditional Wooden Gear Designs?

Integrating modern technology opens up exciting possibilities. Using digital design tools like CAD enables me to create complex gear arrangements that would be nearly impossible to craft by hand. Additionally, incorporating small electronic components—such as tiny motors or sensors—can turn a purely mechanical toy into an interactive experience. For example, embedding a low-voltage motor controlled by a microcontroller can animate certain parts, adding an element of surprise and engagement. This fusion of traditional craftsmanship and modern tech not only broadens creative horizons but also appeals to a new generation of enthusiasts eager for innovative playthings. If you’re interested, exploring resources like interactive Arduino projects can help you start integrating electronics into your woodworking.

Would you like to share your experiences with modernizing traditional wooden toys or have questions about blending tech with craftsmanship? Feel free to comment below—I love hearing about your projects and ideas. The journey of mastering intricate gear systems is ongoing, and each new technique brings fresh inspiration and challenge. Keep experimenting, learning, and pushing the boundaries of what’s possible with wood and innovation!

Innovating with Custom Gear Profiles and Tooth Geometry

One of the most exciting aspects of refining my craft involves exploring alternative gear tooth geometries beyond the classic involute design. Cycloidal and epicycloidal profiles, for instance, can significantly reduce backlash and improve meshing efficiency, resulting in smoother motion and more realistic kinetic effects. Employing CAD software like Fusion 360 allows me to digitally experiment with these profiles, ensuring precision before transferring designs to wood. Integrating these advanced tooth geometries demands meticulous measurement and cutting, often requiring high-precision tools such as CNC routers or fine-tipped scroll saw blades. As I delve into this realm, I find that pushing the boundaries of traditional gear design opens up a world of possibilities for creating more sophisticated and engaging wooden toys. For further insights, consulting authoritative resources like master guides on mechanical design helps deepen my understanding of gear dynamics and tooth optimization.

Harnessing Mechanical Advantage for Intricate Motion Sequences

Designing levers and linkages that leverage mechanical advantage allows me to craft toys with complex, captivating motion patterns. By adjusting lever arm lengths and pivot points, I can amplify small inputs into large, fluid movements that enchant and educate. Experimentation is key; I often create prototypes with varying configurations, observing how each adjustment influences motion. Multiple lever systems within a single toy can produce cascading effects, transforming simple rotations into mesmerizing sequences. Achieving precise control over these mechanisms requires patience and iterative testing, but the results—an intricate dance of gears and levers—are truly rewarding. To expand my knowledge, I frequently review advanced tutorials and case studies, which inspire innovative solutions and refine my craftsmanship. If you’re curious about integrating such complex motion systems into your projects, I recommend exploring creative DIY craft techniques for inspiration.

Integrating Modern Technology with Traditional Wooden Gear Systems

One of the most compelling frontiers is merging age-old woodworking skills with contemporary electronics. Using microcontrollers like Arduino, I can add sensors, motors, and programming to animate my kinetic toys, creating interactive experiences that blend craftsmanship with technology. For instance, embedding a tiny motor controlled by a microcontroller can drive a gear train, producing synchronized movements that mimic real-world machinery. This fusion not only elevates the aesthetic and functional complexity but also broadens the educational scope for users, demonstrating principles of automation and robotics. As I experiment with these integrations, I rely on comprehensive guides such as interactive Arduino projects to ensure reliable implementation. The synergy of traditional woodworking and modern tech offers endless creative possibilities—are you ready to explore this innovative combination? Share your ideas or questions, and let’s push the boundaries of kinetic design together.

What are the best practices for maintaining precision when combining mechanical systems with electronics in wooden toys?

Maintaining precision requires careful planning and manufacturing. Ensuring tight tolerances in gear cutting, selecting stable materials, and controlling environmental factors like humidity are crucial. Additionally, designing modular components facilitates adjustments and repairs, preserving accuracy over time. Regular calibration of electronic components and using high-quality connectors prevent misalignments and signal loss. As I integrate these elements, I document each step meticulously, enabling consistent results across projects. For comprehensive strategies, exploring expert techniques on advanced craftsmanship can provide valuable insights. Embracing this blend of mechanical finesse and technological innovation elevates my work, inspiring others to embrace the future of handcrafted kinetic toys.

Things I Wish I Knew Earlier (or You Might Find Surprising)

Mastering Material Selection

Choosing the right wood was a game-changer for me. I used to think all hardwoods are the same, but discovering the benefits of maple and walnut for gear teeth improved my precision and durability significantly. It’s worth spending extra time on material research before starting a project.

The Power of Patience

Building intricate gears taught me that rushing leads to mistakes. Taking my time, especially during measuring and cutting, ensures smoother motion and a better finish. Patience truly is a virtue in woodworking and mechanical craft.

Importance of Fine-Tuning

Initially, I overlooked how small adjustments could dramatically improve gear mesh. Now, I spend time testing and fine-tuning each gear connection, which makes the difference between a clunky toy and a silky-smooth kinetic masterpiece.

Leveraging Technology

Using CAD software for designing gear profiles saved me from many trial-and-error sessions. It’s incredible how digital tools can help visualize complex gear systems before physical creation, saving time and materials.

Understanding Gear Ratios

Learning about gear ratios opened a new realm of possibilities. I could create more dynamic motion by experimenting with different gear sizes, which enhanced both the educational and aesthetic value of my projects.

Resources I’ve Come to Trust Over Time

- Fusion 360: This CAD software transformed my gear design process, offering precision and flexibility. I highly recommend it for anyone serious about detailed mechanical projects.

- Instructables: The DIY community there is vibrant, and their step-by-step guides helped me troubleshoot and learn new techniques efficiently.

- Wood Magazine: Their articles on hardwood properties and finishing techniques have been invaluable for achieving professional-looking results.

- YouTube Channels like “Woodworking for Mere Mortals”: These channels provide accessible tutorials that inspired my initial projects and ongoing learning.

Parting Thoughts from My Perspective

Exploring the world of DIY wooden gears and kinetic toys has been an incredibly rewarding journey. The key takeaway is that patience, proper material choice, and leveraging modern design tools can elevate your projects from simple crafts to intricate works of art. If this story resonated with you, I’d love to hear your experiences or questions in the comments. Sharing our learning journeys makes the craft even more enjoyable. Feel free to pass this along to anyone interested in combining traditional woodworking with mechanical innovation—there’s always something new to discover in this creative realm.

Reading through your detailed journey into building kinetic wooden toys really resonated with me, especially your emphasis on patience and material selection. I’ve recently started experimenting with creating simple gear trains and can definitely attest to the importance of precise measurements and smooth finishing. I especially liked your mention of using CAD software for designing gear profiles – it’s a game-changer for ensuring accuracy in intricate designs. One challenge I’ve encountered is achieving the perfect gear mesh without excessive friction, and your advice on using natural oils like beeswax is very helpful. Have you ever experimented with different woods to see how they affect the gear motion or durability? I’m curious if certain grains or densities work better for high-precision gear teeth. It’d be great to hear your thoughts or any additional tips for refining gear meshing and achieving that silky-smooth movement in wooden toys.

Your narrative truly resonates with me, especially the blend of patience and precision required in crafting these intricate wooden toys. I’ve been experimenting with similar projects, focusing on the importance of selecting the right type of wood for different components. For example, I’ve noticed that harder woods like maple tend to provide better durability and smoother gear engagement, which reduces friction over time. Additionally, maintaining tight tolerances is critical; I often use digital calipers to ensure that each gear tooth is precisely sized. I wonder, have you found that certain finishing techniques, like micro-sanding or applying specific oils, significantly improve the gear’s performance? I’ve been exploring natural waxes, such as beeswax, to lubricate and protect the surfaces. Also, do you have any tips on how to troubleshoot when gears seem to slip or bind slightly during operation? Sharing these insights could help others in the community refine their craft, especially when dealing with the delicate balance of gear meshing and smooth motion.