My First Encounter with Miniature Steam Engines: A Spark of Curiosity

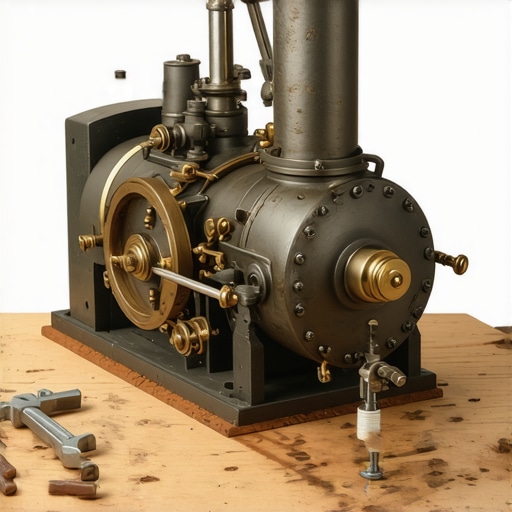

Ever since I was a kid, I was fascinated by the intricate workings of steam engines. That curiosity never waned, and years later, I decided to embark on a rewarding project: building my own DIY miniature steam engine. I remember browsing through various tutorials and feeling both excited and overwhelmed at the prospect of creating a functional metal model from scratch.

Why I Chose to Build a Metal Model Steam Engine

After diving into the world of DIY projects, I realized that a metal miniature steam engine combines engineering, craftsmanship, and creativity. It’s a perfect way to learn about thermodynamics and mechanical design while creating a stunning display piece. Plus, the sense of achievement when your engine finally chugs to life is unparalleled. I also discovered that such projects can be both educational and incredibly satisfying, especially when you see your model running smoothly.

Getting Started: Planning and Gathering Materials

My first step was thorough research. I explored detailed guides like step-by-step DIY guides to ensure I understood the process. I gathered high-quality metal components, including brass, steel, and copper, which are essential for durability and aesthetic appeal. I also invested in basic machining tools such as a mini lathe and drill press, which made the process both manageable and enjoyable.

My Personal Challenges and Breakthroughs

Building a miniature steam engine from scratch was not without hurdles. Precise measurements and careful assembly were crucial. I vividly recall the moment I tested my first piston movement; it was both nerve-wracking and exhilarating. I learned that patience and attention to detail are key. For example, ensuring perfect sealing of the cylinder prevented leaks and improved performance. I also took inspiration from resources like DIY projects for beginners to refine my techniques.

How Did I Make It Work? Tips for Success

My main advice is to start small and gradually improve your skills. Use quality materials, follow detailed instructions, and don’t hesitate to seek advice from experienced hobbyists in online forums. I found that experimenting with different lubricants reduced friction, and I also upgraded my boiler design to increase efficiency. Remember, building a steam engine is a blend of engineering and artistry—don’t rush the process.

What’s the Most Rewarding Part of Building a Metal Miniature Steam Engine?

For me, it’s the moment when the engine actually runs, producing tiny puffs of steam and mechanical movement. Seeing my hard work come alive gave me immense pride, and it’s a feeling I cherish deeply. If you’re considering a similar project, I encourage you to explore related resources like building DIY systems for inspiration and guidance.

If you’ve ever built or dreamed of building a miniature steam engine, I’d love to hear your experiences or tips. Sharing knowledge helps us all grow as DIY enthusiasts and craft artists!

Unveiling the Intricacies of Precision Machining for Steam Engines

As you delve deeper into the craft of building miniature steam engines, understanding the nuances of precision machining becomes essential. Achieving perfect fits for pistons, cylinders, and valves requires not only high-quality tools but also a keen eye for detail. Utilizing a mini lathe with fine-tuning capabilities allows hobbyists to craft components with tolerances that ensure optimal performance. Moreover, selecting the right materials—such as brass for its machinability and copper for thermal conductivity—can significantly influence the engine’s durability and aesthetic appeal. For those interested in elevating their skills, exploring advanced techniques like complex origami structures can enhance your understanding of precision and detail in small-scale projects.

The Art of Sealing and Lubrication: Ensuring Smooth Operation

One of the most common challenges in miniature steam engine construction is achieving effective sealing to prevent steam leaks. Expert hobbyists often experiment with different gasket materials, such as high-temperature silicone or graphite sheets, to find the perfect seal. Lubrication, too, plays a vital role; using the right lubricants like light machine oil or specialized high-temperature greases minimizes friction and wear on moving parts. Precision in assembly, combined with meticulous testing, ensures that your engine runs smoothly and reliably. For further insights on optimizing your engine, consider reviewing advanced sealing techniques that can be adapted for small mechanical systems.

Advanced Techniques for Enhancing Performance and Aesthetics

As you gain confidence, experimenting with surface treatments can add both beauty and function to your miniature steam engines. Techniques such as bead blasting can give a matte finish, while polishing reveals a mirror-like shine that highlights the craftsmanship. Applying heat-resistant paints or patinas adds an artistic touch, making your models stand out as display pieces. Additionally, integrating innovative designs like sculptural art from scrap metal can inspire unique aesthetics. Remember, the key is balancing form and function—each detail contributes to the overall performance and visual appeal of your miniature masterpiece.

What’s the Most Critical Skill to Master When Building Small-Scale Steam Engines?

From an expert perspective, mastering the art of patience and meticulous measurement is paramount. Every component, from the tiny pistons to the elaborate valve gear, demands precision to function correctly. Even minor deviations can lead to leaks or inefficient operation. Developing a methodical approach—double-checking measurements, ensuring clean surfaces, and testing fit—can dramatically improve your success rate. Practicing on scrap materials before working on your final pieces can also help refine your skills without risking costly components. For those looking to deepen their understanding, exploring building DIY systems offers valuable insights into methodical planning and execution that are transferable to miniature engine projects.

If you’re passionate about refining your miniature steam engine craft, I encourage you to share your experiences or ask questions in the comments. Connecting with fellow enthusiasts can open new avenues for learning and inspiration!

Refining Your Craft: The Fine Line Between Precision and Artistic Expression

Building miniature steam engines is a journey that intertwines technical mastery with artistic sensibility. Over the years, I’ve learned that achieving perfect fits for components like pistons, cylinders, and valves requires not just high-quality tools but an intuitive understanding of material behavior and meticulous craftsmanship. It’s fascinating how slight deviations—mere fractions of a millimeter—can influence the engine’s performance or its visual appeal. This delicate balance between engineering precision and aesthetic finesse makes each project uniquely rewarding.

Deepening Your Technical Arsenal: Advanced Machining Techniques

To push beyond basic techniques, exploring advanced machining methods such as complex origami structures can be surprisingly beneficial. These methods develop your spatial awareness and fine motor skills, translating into more refined parts for your steam engines. For example, mastering fine-tuning on a mini lathe enables you to create components with tolerances that ensure leak-proof cylinders and smooth piston movements. I fondly recall my first successful sealing, a moment where patience and precision converged, giving me a sense of achievement that transcended mere mechanical function.

Harmonizing Performance and Aesthetic Detailing

Once your components fit perfectly, the next frontier is enhancing both their performance and visual appeal. Techniques such as bead blasting can provide a matte, industrial look, while polishing reveals a mirror shine that accentuates craftsmanship. Applying artistic touches like subtle patinas or heat-resistant paints transforms functional models into miniature sculptures, capable of captivating viewers with their intricate details. I once experimented with a custom heat-resistant blue finish that beautifully complemented the brass fittings, elevating the overall aesthetic significantly. Remember, each detail, no matter how small, contributes profoundly to the engine’s character and performance.

Addressing Complex Challenges: Sealing and Lubrication Nuances

One of the most nuanced aspects of miniature steam engine building is achieving reliable sealing. The choice of gasket materials—like high-temperature silicone or graphite sheets—can make or break your project. Experimenting with different lubricants, from light machine oils to high-temperature greases, minimizes friction and wear, prolonging the life of your engine. I’ve found that regular testing and iterative adjustments are key; sometimes, a tiny tweak in gasket thickness or lubricant type results in a smoother, more efficient engine. For those aiming for professional results, reviewing advanced sealing techniques can provide insights adaptable to small-scale systems.

Innovating for Longevity and Artistic Impact

As confidence grows, experimenting with surface treatments and artistic finishes can dramatically impact your models’ durability and visual charm. Bead blasting, polishing, and applying artistic patinas are your tools for creating a display-worthy piece. Integrating design elements inspired by sculptural art from scrap metal can also infuse your models with a unique personality. Remember, balancing form and function is not just an aesthetic choice but a technical necessity—each detail enhances performance and visual storytelling.

What is the most critical skill to master for advanced miniature steam engine building?

From my perspective, patience combined with precise measurement is paramount. Every tiny component demands meticulous attention; even the slightest misalignment can cause leaks or inefficiency. Developing a disciplined approach—double-checking measurements, ensuring clean surfaces, and testing fits—can elevate your craftsmanship significantly. Practicing on scrap materials before working on your main components helps refine your skills without risking costly mistakes. For those eager to deepen their expertise, exploring building DIY systems offers valuable lessons in planning and execution that are transferable to miniature engine projects.

If you’ve found your passion in this craft or want to share your experiences, I invite you to comment below. Connecting with fellow enthusiasts not only inspires but also enriches our collective knowledge in this fascinating hobby!

Refining the Art of Precision Engineering for Miniature Steam Engines

Delving deeper into the craftsmanship of miniature steam engines, I’ve come to appreciate that achieving perfect tolerances is both an art and a science. Utilizing advanced machining techniques such as complex origami structures helps develop spatial awareness and precision—skills that directly translate into creating components with ultra-tight fits. With a high-precision mini lathe, I meticulously tune each part, ensuring leak-proof cylinders and smooth piston operation. A noteworthy moment was when I finally sealed my first piston with a tolerance of less than 0.01 mm, a feat that required patience, calibration, and an understanding of material behaviors.

The Subtle Balance Between Functionality and Artistic Detailing

Once mechanical precision is achieved, the next challenge is elevating the aesthetic appeal without compromising performance. Techniques like bead blasting impart a matte finish, reducing glare and giving a utilitarian look, while polishing reveals a mirror shine that accentuates craftsmanship. Artistic touches, such as subtle patinas or heat-resistant paints, can imbue your models with character. For example, I experimented with a heat-resistant blue finish that complemented brass fittings, transforming the engine from merely functional to a captivating display. Each detail, from the tiny valves to the ornamental fittings, contributes to a cohesive visual story that celebrates both engineering mastery and artistic finesse.

The Nuances of Sealing and Lubrication for Long-Term Reliability

Achieving reliable sealing and optimal lubrication is crucial for sustained performance. I’ve experimented with gasket materials like graphite sheets and high-temperature silicone, noting that the right combination prevents steam leaks and withstands thermal stresses. Lubricants such as high-temperature greases and light machine oils are essential; I’ve found that regular testing and iterative adjustments—like tweaking gasket thickness or switching lubricants—lead to smoother operation. Expert insights, such as those shared in advanced sealing techniques, are invaluable when refining these delicate systems. Proper sealing and lubrication not only improve efficiency but also extend the lifespan of your miniature engine, making it a lasting piece of art and engineering.

Innovative Surface Treatments to Enhance Durability and Aesthetic Impact

Exploring surface treatments opens new avenues for artistic expression and durability. Bead blasting provides an industrial matte finish, while polishing creates a reflective surface that highlights fine details. Applying artistic patinas or heat-resistant paints allows for creative customization—I’ve crafted engines with a vintage copper patina and metallic blue accents, which garnered admiration. Incorporating design elements inspired by sculptural art from scrap metal can further personalize your models, blending artistry with engineering. Striking this balance between form and function transforms a mechanical model into a true work of art that commands attention and admiration.

What Advanced Techniques Should I Explore to Elevate My Miniature Steam Engine Craft?

From my perspective, mastering multi-layered surface treatments like heat-resistant coatings and intricate patination processes can significantly elevate your projects. Incorporating origami-inspired precision folding techniques enhances not only the aesthetic detail but also the structural integrity of complex components. Additionally, exploring sculptural welding allows for creating artistic fittings and decorative elements that elevate the visual narrative of your models. These advanced methods require patience and practice, but they reward you with uniquely detailed and durable miniature engines. I encourage fellow enthusiasts to experiment boldly and share their breakthroughs—collaborative learning accelerates mastery in this refined craft.

If you’re eager to push your skills further or have experiences to share, I invite you to engage with the community. Your insights can inspire others and foster a deeper appreciation for this intricate form of craftsmanship. Remember, every detail you refine brings your miniature steam engine closer to becoming a timeless masterpiece of engineering and artistry.

Things I Wish I Knew Earlier (or You Might Find Surprising)

Patience Is a Virtue

When I first started building miniature steam engines, I underestimated how critical patience is. Rushing through assembly often led to mistakes and leaks. Taking your time to measure and test each part carefully makes all the difference in the final performance.

Materials Matter More Than You Think

Choosing the right materials, like brass for its machinability or copper for thermal conductivity, can significantly impact durability and aesthetics. I learned this the hard way when using subpar metals resulted in corrosion and performance issues.

The Power of Good Documentation

Keeping detailed notes and sketches of your build process helps troubleshoot problems later. I wish I had documented more; it would have saved me hours of frustration trying to remember what worked and what didn’t.

Small Details Make a Big Difference

Sealing tiny gaps and choosing appropriate lubricants can prevent leaks and reduce wear. I discovered that even a tiny misalignment could cause inefficiency, so meticulous assembly is vital.

Online Communities Are Invaluable

Joining forums and social media groups gave me access to experienced hobbyists’ advice. Sharing my progress and asking questions accelerated my learning curve and inspired new ideas.

Resources I’ve Come to Trust Over Time

- DIY Guides on Diykutak: Their detailed step-by-step tutorials helped me understand the intricacies of building miniature steam engines, making complex tasks more manageable.

- Machining and Metalworking Resources: Websites dedicated to precision machining taught me about tolerances and material selection, essential for creating reliable models.

- Hobbyist Forums and Social Media: Communities like Reddit and specialized Facebook groups provided support, troubleshooting tips, and inspiration from fellow builders.

- Artisan Craft Websites: Exploring artistic finishes and surface treatments expanded my creative options, making my models more unique and visually appealing.

Parting Thoughts from My Perspective

Building miniature steam engines has been an incredibly rewarding journey, blending engineering with artistry. From understanding the importance of patience and material choice to leveraging the support of online communities, every step has enriched my skills and appreciation for this craft. If you’re passionate about this hobby, I encourage you to dive in with curiosity and patience. Remember, each small detail and every challenge overcome are part of the rewarding process. If this resonated with you, I’d love to hear your thoughts or experiences. Feel free to share your stories or ask questions in the comments—let’s keep inspiring each other in this fascinating world of miniature steam engines!